Eucalyptus vs Acacia Core Veneer – Which is Better for Export Plywood?

🌟 Quick Summary

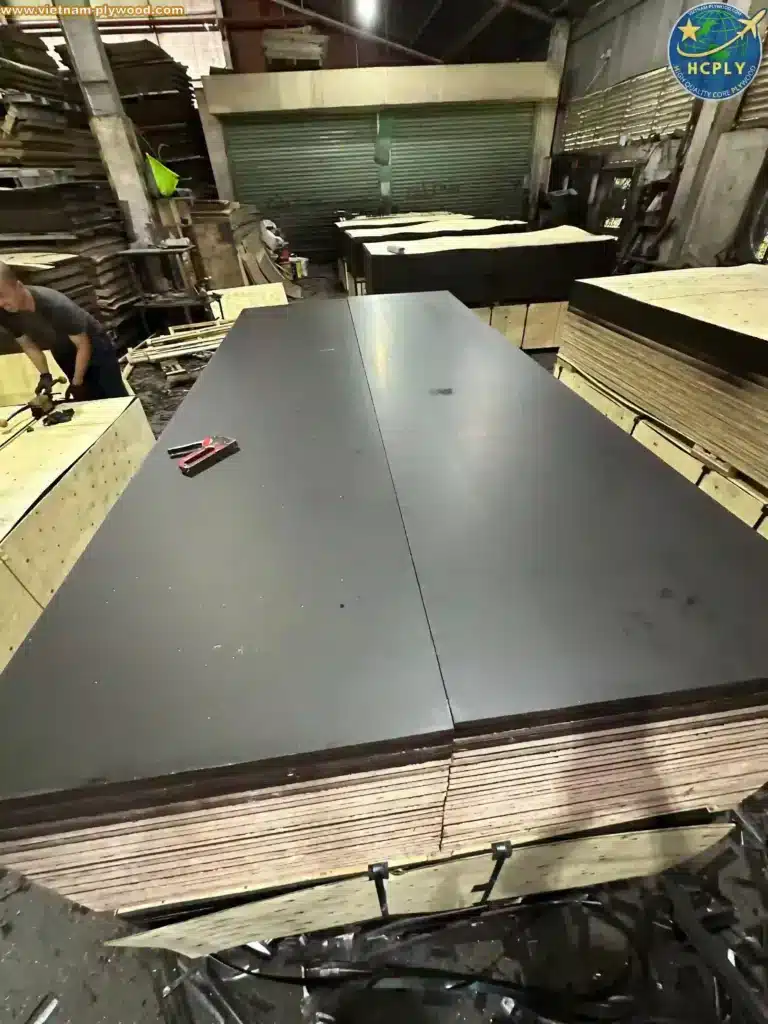

Matt plywood Vietnam—also known as unfaced plywood—is a specialized panel without decorative face veneers, designed for downstream processing like lamination, veneering, or further machining. This guide explains the characteristics of raw core plywood suppliers Vietnam, the benefits of unfaced boards, and how HCPLY delivers export-grade products for manufacturers needing flexibility in surface finishing.

Eucalyptus vs Acacia Core Veneer – Which is Better for Export Plywood?

Quick take: If you prioritize strength and long-term durability, choose eucalyptus core veneer. If you prioritize light weight and cost, choose acacia core veneer. Both can produce excellent export plywood when dried, glued, and calibrated correctly.

1️⃣ 🌏 Why Core Veneer Choice Matters for Export Plywood

In plywood engineering, the face veneer sells the look, but the core veneer carries the load. For global buyers importing from Vietnam, selecting between eucalyptus core veneer and acacia core veneer determines density, screw-holding, bending strength, and logistics cost. The right choice improves project lifespan, reduces warranty claims, and stabilizes supply. Vietnamese mills can deliver both species as single-core or mixed-core constructions to hit your performance and price targets for export plywood.

2️⃣ 🌿 Eucalyptus Core Veneer: High Strength, High Stability

Eucalyptus core veneer is naturally dense (typically 520–650 kg/m³ depending on region and drying). That density translates to:

- Superior bending strength & MOE → floors, formwork, truck decking.

- Outstanding screw-holding → cabinet carcasses, heavy-duty fixtures.

- Better impact resistance → pallets and industrial packaging.

Process tips for mills: higher platen pressure, longer press time, and careful glue spread to penetrate dense fibers. With phenolic/WBP systems, eucalyptus-based export plywood passes severe boil tests and cyclic humidity tests, keeping panels flat and bonded over years.

Trade-offs: heavier boards increase freight cost per container; price per m³ is often higher than acacia; sanding needs tighter grit control to avoid burnishing dense surfaces.

3️⃣ 🌳 Acacia Core Veneer: Lightweight, Cost-Optimized

Acacia core veneer (roughly 430–560 kg/m³) gives you:

- Lower weight → cheaper ocean freight, easier site handling.

- Competitive cost → attractive for price-sensitive tenders.

- Good dimensional stability when kiln-dried to 8–12% MC.

With correct pressing and glue lines, acacia produces smooth, calibrated export plywood ideal for RTA furniture, case goods, and general interiors. It accepts melamine or UV coatings nicely thanks to a friendlier surface for finishing.

Watchouts: density and screw-pull values are typically lower than eucalyptus; edges need proper sealing for humid markets; MR glue systems must be matched carefully to the end-use or upgraded to WBP for higher humidity.

4️⃣ ⚖️ Side-by-Side Comparison (Engineer’s View)

| Criterion | Eucalyptus Core Veneer 🌿 | Acacia Core Veneer 🌳 |

|---|---|---|

| Density / Weight | Higher → stronger but heavier | Lower → easier handling & lower freight |

| Bending & Screw Holding | Excellent 💪 | Good 👍 |

| Moisture Resistance (with WBP) | Very good, holds after cyclic tests | Good, but needs better edge sealing |

| Price Level | Medium–High | Low–Medium |

| Best Fits | Structural, flooring, pallets, shuttering | Furniture, interiors, packaging |

| Risk Profile | Lower risk of core crush/gap print-through | More sensitive to over-drying/edge absorption |

Both species can meet export specs; the press recipe, veneer grading, and glue system decide the final performance more than species alone.

5️⃣ 🧪 Bonding & Glue Systems That Make or Break Performance

- Phenolic (PF) / WBP → exterior, marine, film-faced panels; pairs superbly with eucalyptus core veneer for high-reuse shuttering.

- Melamine (MUF) → interior/humid interiors; common for acacia core veneer furniture panels.

- Process essentials: glue spread 160–220 g/m² per single line (spec-dependent), platen pressure 1.0–1.4 MPa, sufficient temperature/press time for species density, and post-press conditioning to equalize MC before sanding.

6️⃣ 📏 Calibration, Tolerance, and Surface Readiness

Export buyers increasingly demand tight tolerances:

- Thickness: ±0.3 mm standard; calibrated export plywood can reach ±0.15–0.2 mm.

- Sanding: 180–240 grit for UV/laminate lines; avoid glaze on dense eucalyptus.

- Gaps/Overlaps: Core scarfing & automatic jointing reduce telegraphing through face veneers.

Well-calibrated eucalyptus core veneer yields rock-solid feel; well-dried acacia core veneer gives lighter panels without wobble.

7️⃣ 💧 Moisture Strategy for Different Climates

- Tropics/Middle East: target 8–10% MC; insist on edge sealing and balanced layup.

- EU/UK: 8–12% MC; CARB/E1 documents; recommend acclimatization on site.

- India: wide climate variation → request container desiccants & vent inspections.

Controlling MC is crucial for both eucalyptus core veneer and acacia core veneer to arrive flat and ready.

8️⃣ 📦 Logistics, Costing & Sustainability

- Weight economics: eucalyptus fills weight limits early; acacia can pack more sheets per box.

- Sustainability: both are plantation species in Vietnam; pair with FSC Mix/100% for institutional buyers.

- Documentation: ask for layup drawing, press logs, and batch COA. For high-stakes projects, request 3rd-party bond tests before shipment.

9️⃣ 🛠️ Application Playbook (Choose by Use Case)

- Formwork/Scaffold/Truck Floors → eucalyptus core veneer + PF/WBP; film overlay for high reuse.

- Kitchen & Wardrobe Carcasses → acacia core veneer + MUF; calibrated/UV top for quick assembly.

- Export Crates & Heavy Packaging → mixed core (eucalyptus in center, acacia cross-bands) to balance cost and stiffness.

- Premium Furniture Panels → eucalyptus for thin strong web frames; acacia for panels where weight limits apply.

🔟 ❓Quick FAQ

Is eucalyptus always stronger? Generally yes due to higher density, but poor pressing can ruin any species.

Can I mix cores? Yes—mixed cores optimize cost/strength.

Which core is greener? Both are plantation-grown; choose suppliers with FSC/PEFC + low-emission resins.

What’s best for export plywood to humid markets? Eucalyptus core + WBP, or acacia core with strict edge sealing and WBP glue.

✅ Takeaway

Choose eucalyptus core veneer when strength, screw holding, and long service life are non-negotiable. Choose acacia core veneer when logistics cost, weight, and price matter most. With the right specs and QC, either core can produce reliable export plywood that wins repeat orders.