How to Check Vietnam Plywood Quality Before Shipping?

🛠 How to Check Vietnam Plywood Quality Before Shipping – HCPLY’s Comprehensive Buyer’s Guide

Importing plywood is a serious investment, and when sourcing from Vietnam, a complete plywood inspection Vietnam process is essential to protect your order. At HCPLY – Vietnam Plywood Manufacturer & Supplier, our Vietnam plywood quality control system is designed to guarantee that every buyer receives panels that meet or exceed expectations. This guide explains, step-by-step, how to check Vietnam plywood quality like a professional.

1️⃣ Visual Surface Inspection – The First and Most Critical Step

The surface tells a big part of the quality story:

- Look for a uniformly smooth veneer with consistent grain direction and color tone.

- Detect any surface defects early: overlaps, sanding marks, open joints, mineral streaks, or repairs.

- For decorative faces like Okoume, Bintangor, Birch, or Poplar, ensure there are no visible discolorations or filler patches.

- Compare against your order’s grade specification (AA, BB, BC, CD). Even small deviations can impact your product’s value.

- Use strong lighting and inspect at different angles to spot hidden defects.

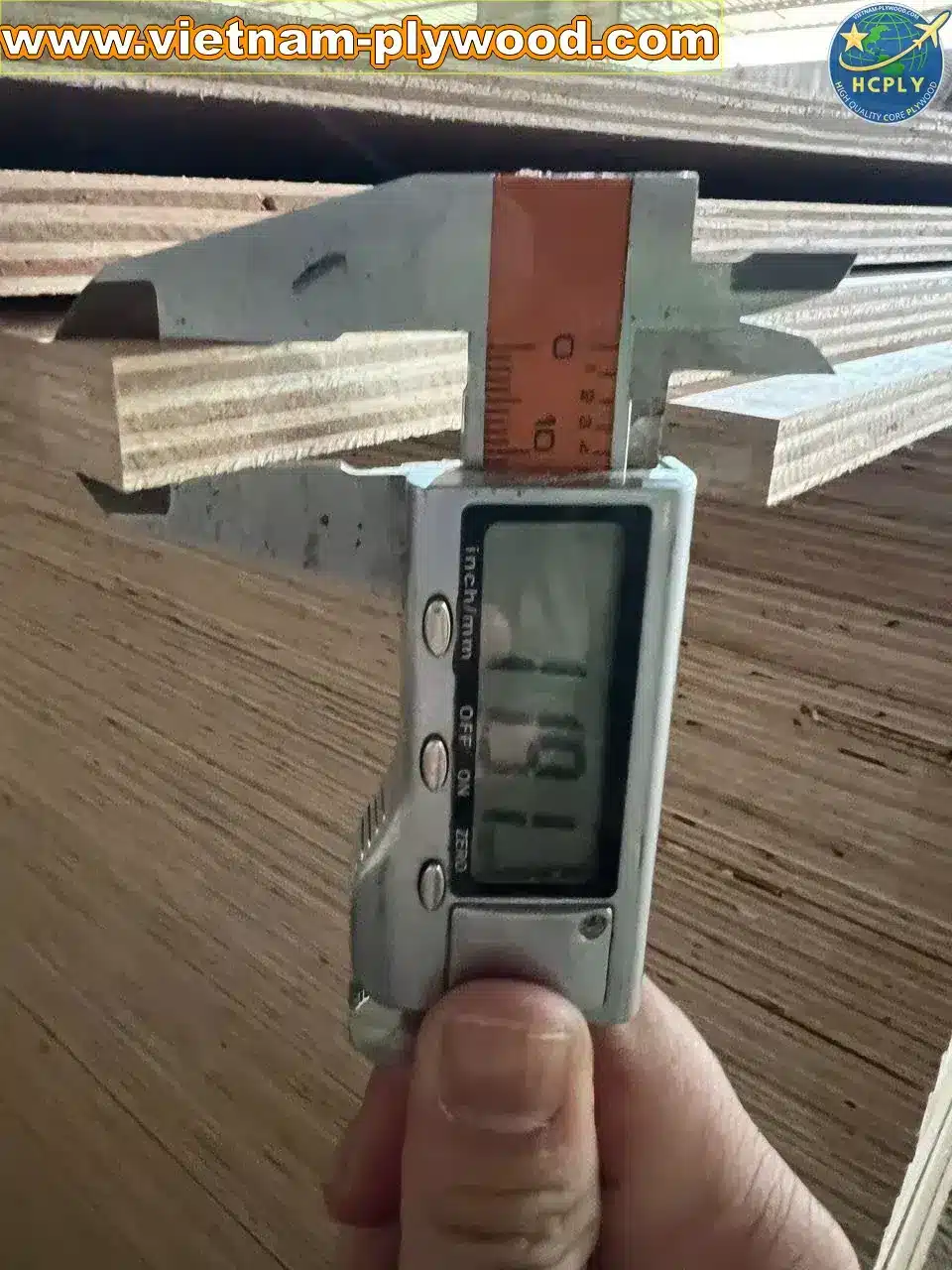

2️⃣ Thickness & Dimension Accuracy – Precision Matters in Every Sheet

- Use a calibrated digital caliper to measure thickness at multiple points, including edges and the center, on at least 5–10 sheets per batch.

- For export-grade plywood, variation should be within ±0.3–0.5 mm.

- Measure length and width with a steel tape and check for squareness by comparing diagonal measurements.

- Out-of-square sheets can cause fitting problems in furniture, cabinetry, and flooring installations.

3️⃣ Core Quality & Bonding Strength – The Heart of Vietnam Plywood Quality Control

- Ask for a core cut sample to see the hidden layers. A well-made core should have tight, gap-free joints.

- Avoid products with large voids, overlaps, or misaligned plies, as they compromise structural integrity.

- Check the glue line: a strong bond will tear the wood fibers before the glue joint fails.

- Confirm glue type matches your order — WBP Phenolic for exterior or marine use, Melamine for moisture resistance, and MR for interior use.

- A proper plywood inspection Vietnam should also include hot water or boil tests for WBP products.

4️⃣ Moisture Content Control – Prevent Warping, Mold, and Delamination

- Target moisture content for export plywood: 8–14% (adjust based on the destination climate).

- Use a digital moisture meter and test sheets from different pallets, including those in the center of the stack.

- High moisture can lead to swelling and warping, while overly dry panels can crack during transport.

5️⃣ Edge, Corner, and Trimming Inspection – The Finishing Touch

- Edges should be smoothly trimmed, perfectly square, and free from tear-out.

- Corners must be intact — not crushed, chipped, or frayed.

- Many buyers request painted or sealed edges to provide additional moisture protection during shipment.

- Check that there is no delamination starting at the edges, which can spread during transport.

6️⃣ Glue Bond & Mechanical Tests – When You Need Absolute Assurance

- For high-value orders, conduct destructive testing: bending, impact, and shear tests.

- For structural or marine-grade plywood, verify compliance with specific standards (BS 1088, EN 314, JAS, etc.).

- These tests ensure your plywood can handle stress without sudden failure.

7️⃣ Packing & Label Verification – Protecting Quality Until Delivery

- Check that every bundle is wrapped in waterproof plastic film and strapped securely with steel or PP bands.

- Pallets must be ISPM 15 heat-treated and sturdy enough for long sea voyages.

- Labels should clearly state product name, size, grade, quantity, and production date.

- During Vietnam plywood quality control, we also verify container loading — bundles should be positioned for weight balance and ventilation.

8️⃣ Third-Party Inspection Services – Extra Security for Buyers Abroad

- If you cannot visit the factory, hire a reputable inspection company in Vietnam to perform the final plywood inspection Vietnam.

- Services typically include dimensional checks, visual inspections, moisture testing, and packaging verification.

- HCPLY works with multiple certified inspectors to make this process smooth for our clients.

💬 Final Advice from Lucy:

To ensure a problem-free shipment, combine factory quality control with independent verification before the container is sealed. Whether you’re sourcing for construction, furniture, or distribution, a complete Vietnam plywood quality control process is your best protection. At HCPLY, we integrate these steps into every order so our clients can confidently say they’ve made the right choice when they check Vietnam plywood quality.

📩 WhatsApp +84-975807426 | Email [email protected]