Understanding Thickness Tolerance in Vietnam Plywood

📏 Vietnam Plywood Thickness Tolerance – The Complete Buyer’s & Exporter’s Guide

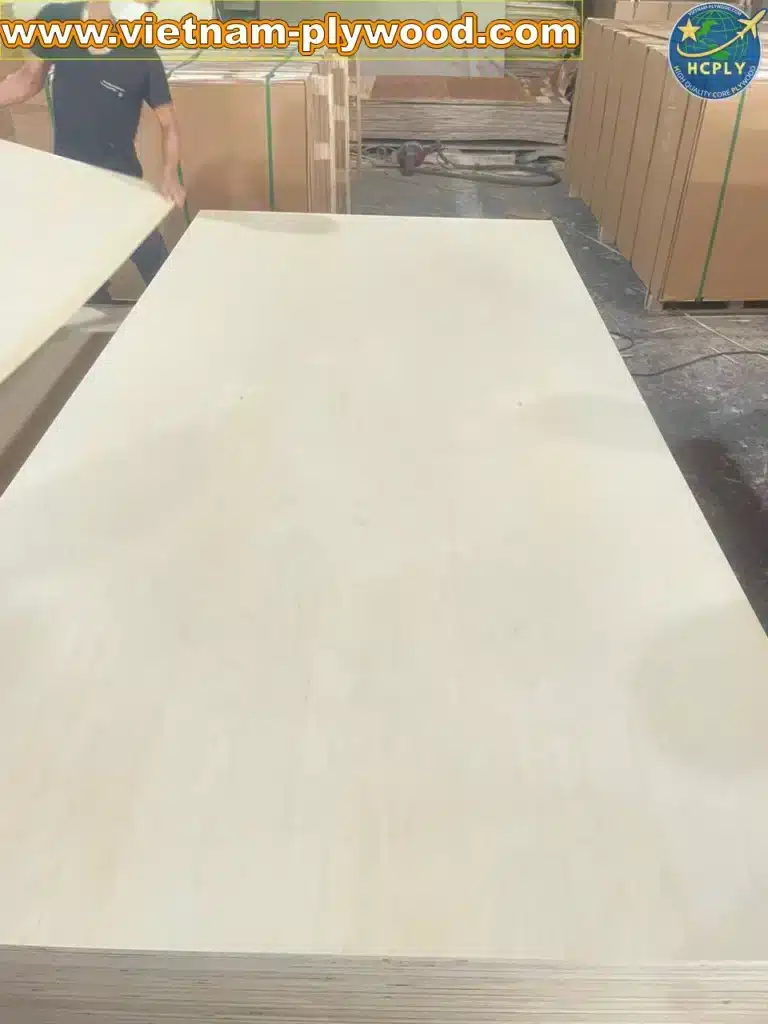

🏆 1. Opening Insight – Why Thickness Tolerance Matters

In the international plywood trade, particularly for Vietnam plywood exports, thickness tolerance is one of the first quality metrics buyers examine. It’s not just a number on a specification sheet — it’s a direct indicator of manufacturing precision, production discipline, and quality control consistency.

When a plywood panel’s actual thickness is outside the agreed tolerance, it can trigger multiple issues:

- 📐 Poor fitting in assembly – Panels may not align with grooves or frames.

- 🏗 Structural concerns – Load-bearing capacity may be compromised.

- 🪵 Lamination challenges – Uneven thickness creates weak glue lines in post-processing.

- 📜 Non-compliance – Risk of failing EN, ISO, or JAS inspections for regulated markets.

For large-scale projects such as commercial interiors, shipbuilding, and prefabricated housing, even a 0.3mm deviation can cascade into costly delays, rework, and potential client dissatisfaction.

🎯 2. International Standards and Vietnam’s Position

Vietnam’s plywood industry follows thickness tolerance guidelines closely aligned with:

- ISO 2426-2 (Plywood – Classification by surface appearance)

- EN 315 (European plywood tolerances)

- JAS (Japanese Agricultural Standard for Plywood)

Typical benchmarks for a 12mm panel:

- 🇯🇵 Japan: ±0.2mm (premium grade requirement)

- 🇪🇺 Europe: ±0.2–0.3mm for furniture/interior grades

- 🌏 General Asian markets: ±0.3–0.5mm

- 🌍 Middle East & Africa: ±0.3–0.5mm (general commercial use)

Observation: Japan and EU markets apply stricter tolerances due to higher product integration standards, while markets like India, Middle East, and Southeast Asia accept slightly wider variations for cost efficiency.

💎 3. Factors Affecting Thickness Tolerance

The final plywood thickness variation is the result of multiple interlinked factors:

- Core Veneer Moisture Content Before Pressing

- Too high: compression after pressing → panel ends up thinner than target.

- Too low: veneer may crack during pressing, causing uneven compression.

- Pressing Temperature and Duration

- Under-heating → incomplete bonding, spring-back effect.

- Over-heating → excessive compression, thinner-than-spec panels.

- Uniformity of Veneer Thickness

- Variations in peeled veneer thickness accumulate through the core stack.

- Glue Spread and Curing

- Inconsistent glue spread can cause uneven bonding layers, subtly affecting final thickness.

- Post-Press Cooling and Conditioning

- Panels should stabilize before sanding to avoid rebound effect.

📦 4. Common Tolerance Ranges in Vietnam Plywood

- 🥇 Premium Grades (AA, BB): ±0.2 – ±0.3mm

Ideal for high-end furniture, architectural joinery, and flooring substrates. - 🥈 General Export Grades (BC, CD): ±0.3 – ±0.5mm

Suitable for mid-range furniture, packaging, and general interiors. - 📦 Utility / Packing Plywood: ±0.5 – ±0.8mm

Accepted in low-cost, non-precision applications where cost is prioritized.

🛠 5. How Manufacturers Control Tolerance

Top Vietnamese factories like HCPLY employ a multi-stage approach:

- Calibrated Sanding Machines – Final finishing to exact thickness.

- Strict Core Veneer Grading – Rejecting overly thick or thin sheets during assembly.

- Regular Calibration of Press Plates – Maintaining uniform pressure and heat distribution.

- In-Line Thickness Gauges – Continuous QC during production, not just post-press.

- Controlled Veneer Storage – Preventing moisture shifts before pressing.

🔍 6. Thickness Issues and Their Impacts

If Vietnam plywood thickness tolerance is exceeded:

- 🪚 Furniture assembly issues – Panels won’t fit precisely into joinery slots.

- 🩹 Glue line gaps – Weak bonding in laminated products.

- ⚠ Reduced structural strength – Particularly critical in flooring and formwork.

- 🚫 Market rejection – Shipments may fail at customs or third-party QC inspections.

📌 7. How Buyers Can Verify Tolerance

A systematic check involves:

- Digital Calipers – Use for accurate measurement to 0.01mm.

- Multiple Points Per Sheet – At least 10 readings, covering center and edges.

- Cross-Panel Checks – Measuring diagonally to detect press unevenness.

- Averaging Method – Compare average to tolerance in sales contract.

💡 Pro Tip: Keep photographic or video proof during measurement to support any claims.

📈 8. The Link Between Tolerance and Market Price

- Tighter tolerance = higher cost due to:

- Premium veneer selection.

- More stringent QC checks.

- Slower production speeds to maintain accuracy.

For premium furniture or architectural panels, the cost increase (often +3–5%) is justified by:

- Faster assembly times.

- Reduced on-site trimming.

- Higher end-user satisfaction.

💬 9. Expert Tip from HCPLY

“Thickness tolerance is not just a technical number — it’s a reflection of manufacturing discipline and a promise kept to the customer.”

— David, Export Project Leader, HCPLY

HCPLY’s export lines are calibrated daily, and every shipment is accompanied by thickness test reports.

🌟 10. Closing Thoughts – Dimensional Accuracy Builds Trust

Maintaining the agreed plywood thickness standards Vietnam is not optional — it’s the foundation of lasting trade relationships.

“Precision is the bridge between promise and delivery.”

By understanding realistic tolerances, buyers can:

- Negotiate fairer prices.

- Avoid unnecessary disputes.

- Build long-term trust with suppliers.

📞 WhatsApp: +84-338616333

✉ Email: [email protected]

🌐 View All Products