Vietnam Film Faced Plywood Technical Specs – What Buyers Need to Know

🏗 Vietnam Film Faced Plywood Technical Specs – Complete Buyer’s Guide

🏆 1. Introduction – Why Film Faced Plywood is Essential

In modern construction and infrastructure projects, Vietnam film faced plywood technical specs are the blueprint for durability, cost efficiency, and structural integrity. The right panel can withstand multiple concrete pours, harsh weather conditions, and rough on-site handling, saving both material costs and labor time.

For importers and contractors, knowing the exact film faced plywood Vietnam specifications ensures:

- Panels last for the expected number of reuse cycles

- Formwork maintains precise dimensions for quality finishes

- Shipping and storage are optimized for performance retention

🎯 2. Applications in Construction

Film faced plywood is one of the most versatile and value-driven building materials in large-scale projects.

Common uses include:

- Concrete formwork for walls, slabs, beams, and columns

- Bridge and tunnel shuttering for civil engineering works

- Reusable panels in precast concrete production

- Temporary flooring for event stages or construction walkways

- Anti-slip surfaces for vehicle ramps and scaffolding platforms

💡 Industry Insight: In Southeast Asia and the Middle East, phenolic-coated formwork panels from Vietnam are often chosen for their balance of price and performance compared to European imports.

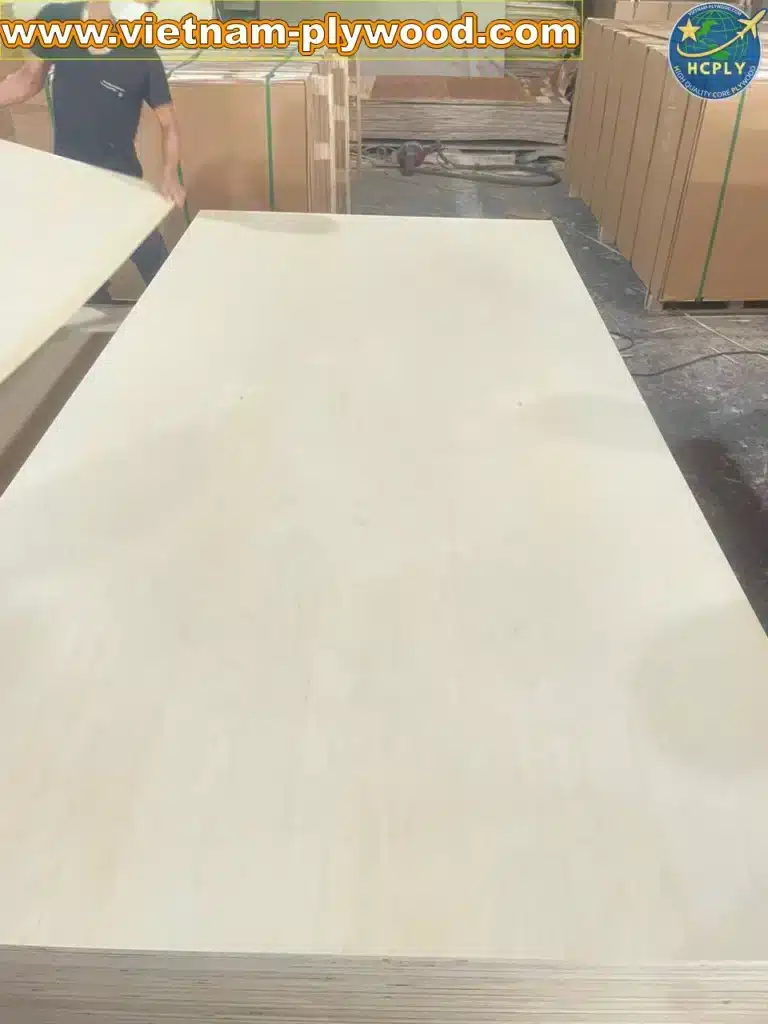

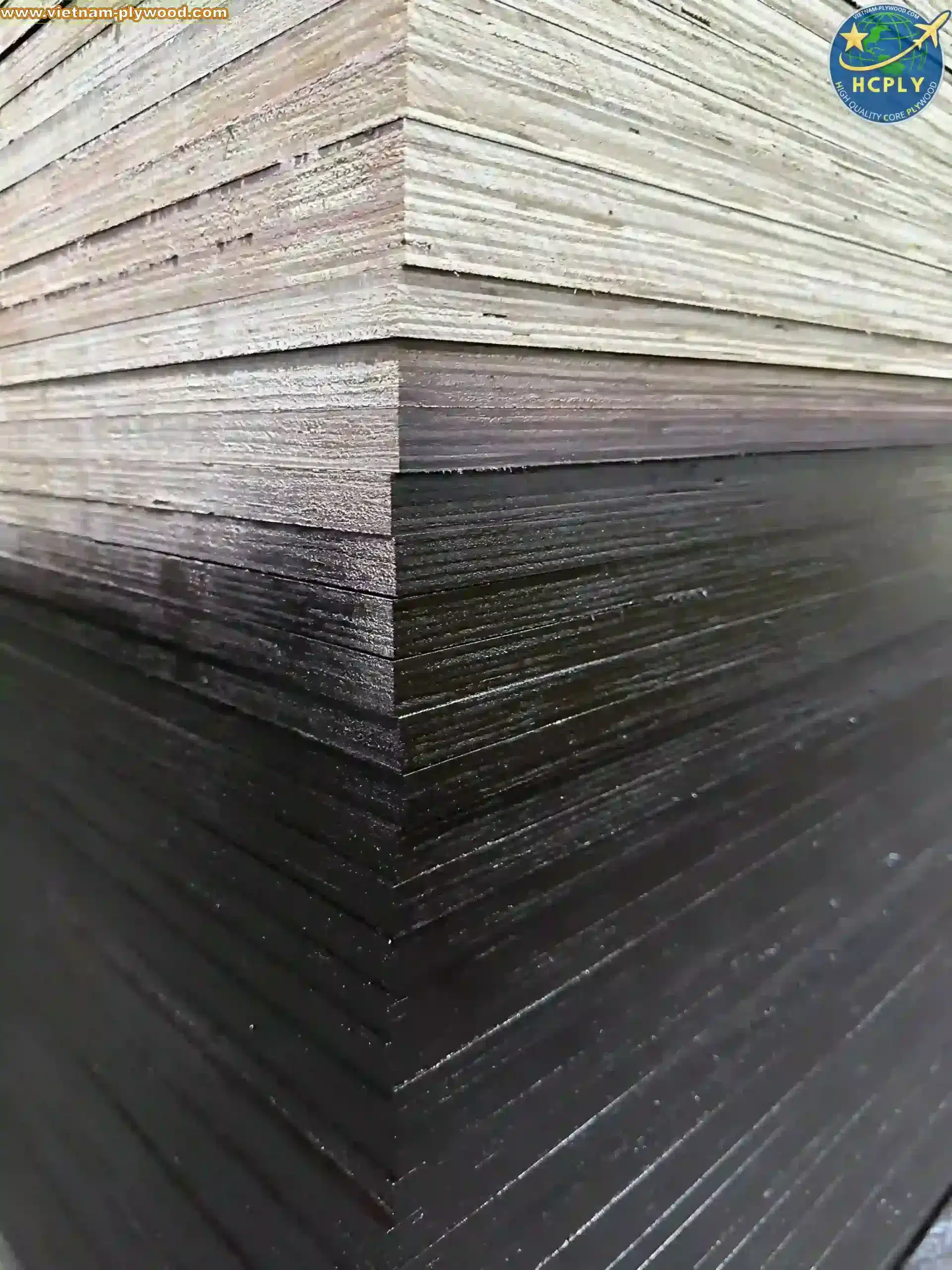

💎 3. Core Material and Construction

Vietnamese film faced plywood is engineered for maximum load-bearing and moisture resistance.

Core species:

- Eucalyptus – high density, excellent screw holding

- Acacia – balanced weight and durability

- Poplar – lightweight, suitable for mid-cycle reuse

- Mixed hardwood – cost-effective compromise between weight and strength

Layer count:

- 9–11 plies → Standard for 15–18 mm

- 13 plies → Heavy-duty for 21 mm or marine-grade projects

Glue type:

- Phenolic WBP – Premium choice for 10–20 reuse cycles in wet conditions

- Melamine WBP – Economical option for 5–10 reuse cycles in dry or mild weather

🔹 H4: Bonding Strength

- Tested according to EN 314-2 Class 3

- Phenolic WBP glue passes 72-hour boiling water test without delamination

- Shear strength maintained even after repeated exposure to concrete and cleaning chemicals

📦 4. Film Coating Types

The film overlay is the first defense against abrasion, moisture, and chemical damage.

Options include:

- Phenolic film (120–220 g/m²) – Superior abrasion and moisture resistance

- Melamine film – More affordable, suitable for short-term or low-reuse applications

- Anti-slip patterned film – Ideal for flooring and staging

- Color variations: Black (most common), Brown, Red, Yellow, or custom branding

💡 Tip: Darker film colors tend to hide concrete stains better, improving appearance after multiple uses.

🛠 5. Standard Sizes and Thickness

Panel sizes:

- 1220 × 2440 mm – Industry standard for compatibility with most formwork systems

- 1250 × 2500 mm – For specialized applications, offering larger coverage per sheet

Thickness options:

- 12 mm – Lightweight, economical for non-load-bearing work

- 15 mm – General-purpose formwork

- 18 mm – Heavy structural elements

- 21 mm – Maximum strength and durability

Weight range:

- 30–40 kg depending on thickness, density, and moisture content

🔍 6. Edge and Surface Protection

Film faced plywood longevity depends heavily on edge sealing and surface integrity.

- Edges: Sealed with 2–3 coats of waterproof acrylic paint

- Surface film: Resistant to scratches, moisture, concrete adhesion, and mild chemicals

- Maintenance: Reseal cut edges immediately after trimming to maintain waterproofing

📌 7. Quality Standards and Testing

Vietnamese film faced plywood can be manufactured to meet:

- EN 636 – Durability classification

- EN 314-2 – Bonding quality for exterior conditions

- BS 1088 equivalent – Marine-grade plywood standards

- ASTM D1185 – Load-bearing tests for industrial pallets and staging

📈 8. Cost Factors

Final pricing is influenced by:

- Film type & weight (Phenolic > Melamine)

- Core material (Eucalyptus > Acacia > Poplar in price & density)

- Glue system (Phenolic WBP > Melamine WBP)

- Number of guaranteed reuse cycles

💡 Cost-saving tip: If your project is short-term, melamine-coated poplar core panels can reduce cost without affecting results.

💬 9. FAQ – Common Buyer Questions

H3: Q1 – How many times can film faced plywood be reused?

Premium phenolic-coated panels with hardwood cores can be reused 10–20 times, depending on handling and cleaning.

H3: Q2 – Can it be cut without damaging the film?

Yes, but edges must be resealed with waterproof paint immediately after cutting.

H3: Q3 – Is phenolic film worth the extra cost?

For projects requiring multiple reuses or exposed to wet weather, yes — the longer life span offsets the higher initial investment.

H3: Q4 – What’s the main cause of short panel life?

Improper handling, dropping, or cleaning with harsh tools can damage the film and reduce reuse cycles.

🚢 10. Logistics and Shipping

- Loading: Typically 50–60 panels per pallet

- CBM calculation:

- 18 mm × 1220 × 2440 mm panel ≈ 0.053 m³ each

- Container capacity:

- 20ft container: ~8–9 pallets (~450–550 sheets of 18 mm)

- 40ft container: ~16–18 pallets

Optimizing thickness and core material can reduce freight cost per use.

🌟 11. Closing Thoughts – Choosing the Right Specs

The right film faced plywood specifications balance reuse cycles, cost efficiency, and structural performance.

“Quality formwork panels don’t just build structures — they build reputations.”

By understanding Vietnam film faced plywood technical specs, importers can confidently select panels that deliver maximum value and durability, ensuring each pour is as precise as the first.

📞 WhatsApp: +84-338616333

✉ Email: [email protected]

🌐 View All Plywood Products