Vietnam Full Poplar Core vs Mixed Core Plywood – Key Differences & Export Guide

1. Introduction – Why Core Composition Matters: A Strategic Choice for Plywood Exporters 🌳

The core of a plywood panel is not just filler; it is its structural heart, defining its fundamental performance characteristics. For international buyers, the choice of core composition is a strategic decision that directly impacts a panel’s structural strength, overall weight, price competitiveness, and its suitability for specific end-use applications.

As a global hub for wood products, Vietnam offers two popular and distinct core options: full poplar core plywood Vietnam and mixed core plywood Vietnam. Understanding the nuanced differences between these two is essential for making an informed purchasing decision that aligns with both technical specifications and market demands. This guide will provide a deep dive into each core type, helping you to confidently choose the right material for your business.

2. The Deep Dive: Full Poplar Core Plywood Vietnam – The Lightweight, High-Aesthetics Champion 🍃

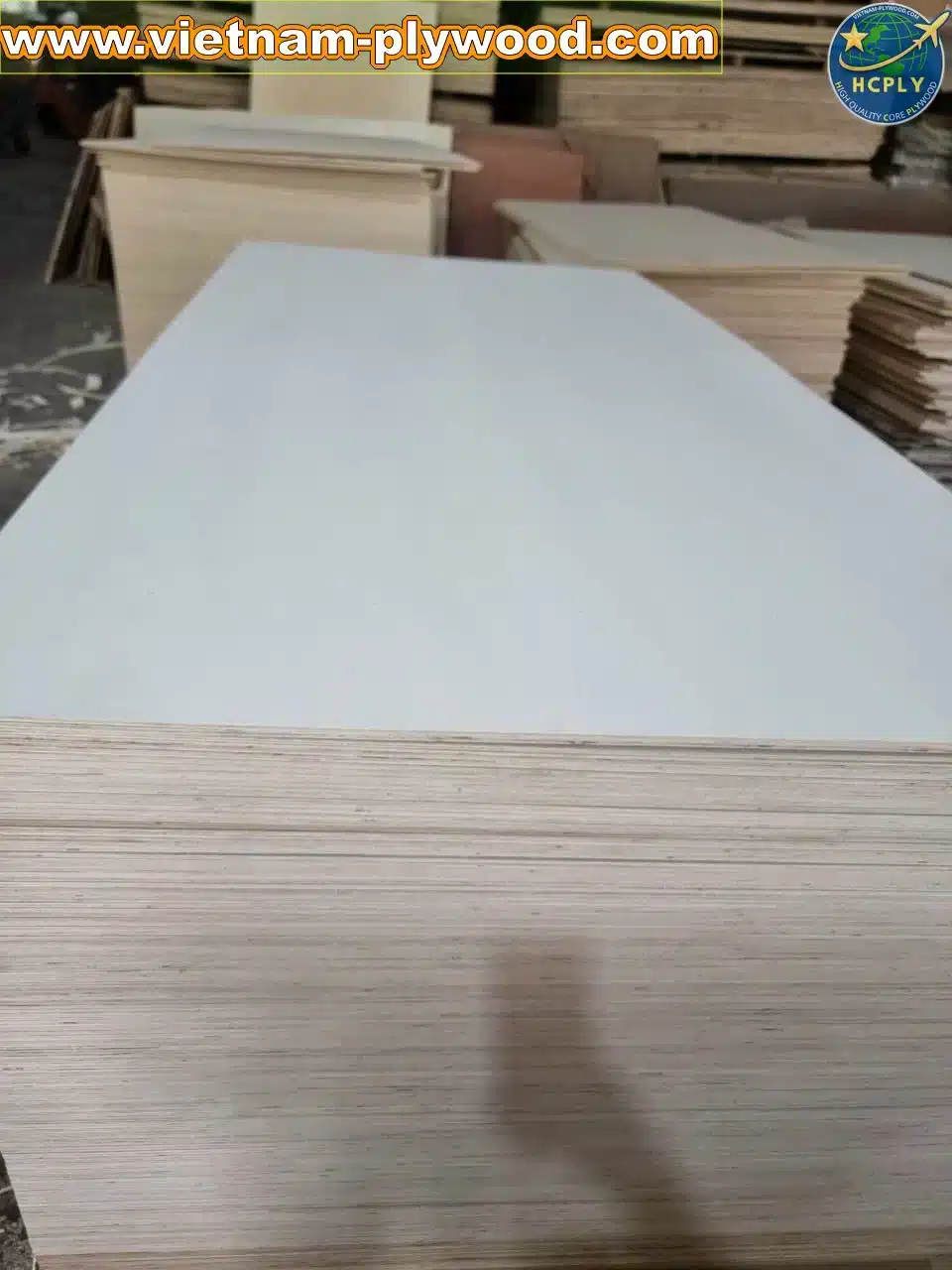

Full poplar core plywood Vietnam is a high-demand product made exclusively from veneers of sustainably harvested poplar. This uniform composition provides a panel with a lower density, typically ranging from 450–500 kg/m³. This low density is not a weakness but a key feature that caters to a specific market segment.

- Key Characteristics and Advantages:

- Exceptional Lightweight Properties: The most significant advantage of full poplar core is its low weight. This translates directly into substantial savings on shipping and logistics costs, making it an economically attractive option for high-volume exports. The reduced weight also makes the panels easier to handle and install, a benefit for furniture manufacturers and builders.

- Superior Surface Quality: Poplar veneers are known for their consistent, fine grain and smooth texture. This makes full poplar core plywood an excellent substrate for high-quality finishing, such as veneering, lamination, or painting. The final product has a clean, uniform appearance that is highly sought after in decorative applications.

- Dimensional Stability: Despite being lightweight, poplar wood offers good dimensional stability, which helps prevent warping and twisting. This is a crucial factor for furniture and cabinetry, where maintaining flatness over time is essential.

- Ease of Processing: Poplar is a soft hardwood, making it easy to cut, shape, and machine without causing significant tool wear, which can improve manufacturing efficiency.

- Ideal Applications: Full poplar core plywood is the go-to choice for premium packaging, lightweight furniture, interior wall paneling, and other decorative applications where aesthetics and reduced weight are primary considerations.

3. The Deep Dive: Mixed Core Plywood Vietnam – The Strong, Durable Workhorse 💪

Mixed core plywood Vietnam is a hybrid engineered product designed to offer a blend of strength and cost-effectiveness. It is constructed using a combination of veneers from poplar and denser hardwoods such as eucalyptus, acacia, or styrax. This strategic layering creates a panel with a higher density, typically between 550–650 kg/m³, giving it superior mechanical properties.

High Structural Strength and Durability: The inclusion of hardwood veneers significantly increases the panel’s strength, making it ideal for structural and load-bearing applications. It has a higher bending strength and better resistance to impact compared to full poplar core.

- Key Characteristics and Advantages:

- High Structural Strength and Durability: The inclusion of hardwood veneers significantly increases the panel’s strength, making it ideal for structural and load-bearing applications. It has a higher bending strength and better resistance to impact compared to full poplar core.

- Excellent Screw and Fastener Retention: The denser hardwood layers provide superior screw-holding strength, ensuring that hardware, hinges, and fasteners remain securely in place, even under stress. This is a non-negotiable feature for heavy-duty furniture and construction.

- Improved Moisture Resistance: Hardwood veneers often have better inherent resistance to moisture, and when combined with a waterproof glue (WBP), mixed core plywood is well-suited for demanding environments.

- Cost-Effective Performance: While slightly heavier and more expensive than full poplar, mixed core offers a cost-effective solution for projects that require the performance of hardwood but at a more competitive price point than pure hardwood plywood.

- Ideal Applications: Mixed core plywood is the material of choice for demanding applications such as concrete formwork, flooring substrates, heavy-duty furniture, and structural components in construction.

4. Comprehensive Comparison: Full Poplar vs. Mixed Core Plywood Vietnam ⚖️

| Feature | Full Poplar Core Plywood Vietnam | Mixed Core Plywood Vietnam | Strategic Implication |

| Density | Light (450–500 kg/m³) | Medium (550–650 kg/m³) | Density directly correlates with weight, shipping costs, and mechanical strength. |

| Strength | Moderate; suitable for decorative use. | High; ideal for structural and load-bearing applications. | A key trade-off: choose based on the required load and durability. |

| Moisture Resistance | Good (with WBP glue) | Very Good (with WBP glue) | Mixed core’s denser layers offer better protection in humid or wet conditions. |

| Screw Holding | Good; suitable for light to medium loads. | Excellent; for secure, durable assembly. | Critical for furniture and construction where fasteners are essential. |

| Weight | Lighter, reducing transportation costs. | Heavier, increasing shipping costs but providing structural integrity. | An important factor for project budgets and logistics. |

5. Price, Glue Options, and Global Market Preferences 📈

- Price and Logistics: Full poplar core plywood is generally more affordable and offers significant savings on shipping. Mixed core plywood, while slightly higher in price, provides a performance-to-cost ratio that is unbeatable for structural applications.

- Adhesive Options: Both core types are available with various glue options, allowing you to tailor the panel to its final environment:

- MR (Moisture Resistant) Glue: Suitable for interior, non-humid applications.

- WBP (Weather and Boil Proof) Melamine or Phenolic Glue: Essential for exterior, marine, or high-humidity environments.

- Market Preferences:

- Europe and Japan: The demand for lightweight, clean-finish products drives a strong preference for full poplar core for furniture and packaging.

- India and the Middle East: Heavy-duty applications like formwork and robust furniture lead to a higher demand for mixed core plywood.

- South America: The market is diverse, with demand for both types based on product category and cost sensitivity.

6. HCPLY’s Commitment to Quality and Customization ✅

As a leading plywood manufacturer and exporter, HCPLY provides both full poplar core plywood Vietnamand mixed core plywood Vietnam with a steadfast commitment to quality. Our rigorous quality control process, from veneer grading to precision pressing, ensures every panel meets or exceeds international standards. We also offer a high degree of customization, allowing you to specify core composition, thickness, face veneer type, and glue to create a product perfectly tailored for your target market and end-use application.

7. Conclusion – The Strategic Choice for Your Business 🌐

The decision between full poplar core plywood Vietnam and mixed core plywood Vietnam is a strategic one that should be made after careful consideration of your project’s unique requirements. By understanding the distinct advantages of each, you can select the core that provides the optimal balance of performance, weight, and cost. HCPLY stands ready to be your trusted partner, offering both expertise and a wide range of customizable products to ensure your business thrives in the competitive global marketplace.

📩 Contact David – Export Project Leader

WhatsApp: +84-338616333

Email: [email protected]

🌐 Website: https://vietnam-plywood.com

What is poplar core plywood?

Poplar core plywood is plywood with its inner layers made from poplar veneer, offering a lightweight structure and smooth surface. HCPLY – Vietnam Plywood Manufacturer & Supplier produces high-grade poplar core plywood for furniture, packaging, and interior use

What are the disadvantages of poplar plywood?

Poplar plywood is softer and less dense than hardwood-core plywood, making it less suitable for heavy load-bearing applications. HCPLY enhances durability through strict veneer selection and strong bonding.

Is poplar plywood any good?

Yes. Poplar plywood is easy to machine, lightweight, and cost-effective, ideal for furniture, cabinets, and packaging. HCPLY ensures export-standard quality with consistent thickness and bonding.

What are the three types of plywood cores?

The main types are:

Veneer core (poplar, eucalyptus, acacia, etc.)

MDF core

Particleboard core

HCPLY offers multiple core options to suit different market demands

Choosing the right plywood type is crucial for ensuring the success of your project. When selecting between full poplar core plywood Vietnam and mixed core plywood Vietnam, consider factors such as strength, weight, cost, and the specific requirements of your application.