Vietnam Packing Plywood Specifications – Complete Guide

📦 Vietnam Packing Plywood Specifications – Complete Export Guide

🏆 1. Introduction – Why Packing Plywood Matters

In global export logistics, Vietnam packing plywood specifications are a decisive factor in the safety of goods, shipping cost efficiency, and compliance with international packaging regulations.

Choosing the right packing grade means:

- Ensuring structural integrity of crates and pallets

- Preventing product damage during rough handling and long transit

- Avoiding unnecessary freight costs due to over-specification

For importers, understanding packing plywood Vietnam allows you to balance cost efficiency with protective performance, ensuring you only pay for the strength you truly need.

🎯 2. Definition and Applications

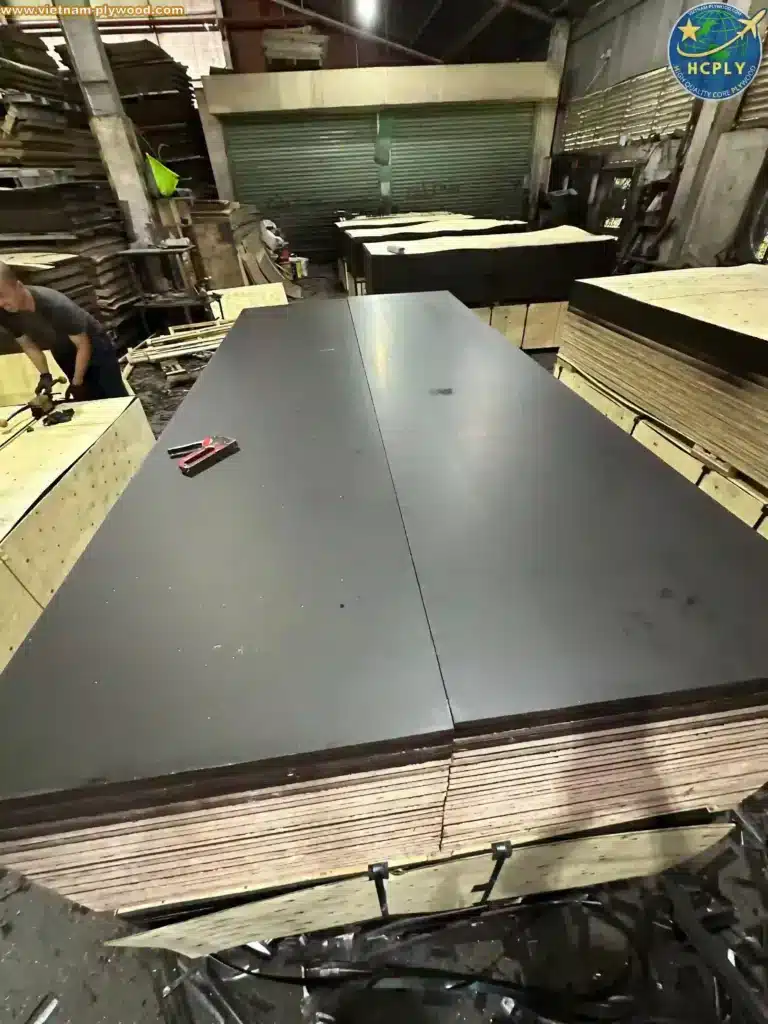

Packing plywood, also called packing grade plywood Vietnam, is an industrial-grade panel manufactured for functional protection, not visual appeal.

Main applications include:

- Export crates for machinery, electronics, automotive parts

- Pallet tops and side panels

- Temporary flooring inside shipping containers

- Protective barriers in consolidated shipments

💡 Tip: If your cargo is sensitive to moisture, selecting the right glue type and edge sealing is critical for protection during sea freight.

💎 3. Materials and Core Construction

Vietnamese packing plywood is built with cost-effective but strong materials:

- Core species: Acacia, Eucalyptus, Styrax, or mixed hardwood combinations

- Face veneer: Low-grade hardwood, Bintangor, or Okoume, primarily for coverage

- Glue type:

- MR (Moisture Resistant) – suitable for dry or short-term shipping

- WBP (Water Boil Proof) – recommended for long-distance sea freight or high-humidity regions

🔹 H4: Layer Configuration

Typical configurations:

- 8–12 mm → 3–5 core layers for crates & pallets

- 15–18 mm → Heavy-duty or reusable crates, often reinforced for stacking strength

Balanced layup is used to prevent warping during transit.

📏 4. Standard Sizes and Thickness

Common dimensions for export plywood Vietnam:

- 1220 × 2440 mm – Most widely available and cost-effective

- Customized sizes available to match specific crate designs

Thickness ranges:

- 5–6 mm – Light protective covering

- 8–12 mm – Standard export crates and pallet decks

- 15–18 mm – Heavy-duty or reusable shipping boxes

📌 Choosing the right thickness prevents over-engineering while maintaining protection.

🛠 5. Technical Specifications

- Moisture content: 8–14% (ideal for export stability)

- Density: 500–650 kg/m³ (varies with species)

- Tolerance: ±0.3–0.5 mm

- Surface finish: Sanded or unsanded (unsanded for economy; sanded for handling safety)

- Edge sealing: Optional for moisture protection in sea freight

- Bonding strength: Tested to meet minimum shear strength standards for packaging plywood

🔍 6. Quality Standards and Testing

Packing plywood for export should meet:

- ISPM-15 compliance (for crates with solid wood components, fumigation/heat treatment required)

- Static load testing for heavy machinery crates

- Bond line tests to ensure veneers remain intact under shipping stress

- Humidity simulation for sea freight destinations

📌 7. FAQ – Common Buyer Questions

H3: Q1 – Is WBP glue necessary for packing plywood?

Not always. For short transit or air freight, MR glue is cost-effective. For sea freight or humid conditions, WBP glue provides longer-lasting protection.

H3: Q2 – Can packing plywood be reused?

Yes. Panels 15mm or thicker with WBP glue can often be reused multiple times, especially if edge-sealed.

H3: Q3 – What’s the cheapest thickness for export crates?

8–9 mm is the most common for lightweight goods, balancing cost and strength. Heavier cargo requires thicker panels.

📈 8. Cost Considerations

Packing plywood is cheaper than furniture-grade plywood due to:

- Lower veneer grades

- Less strict appearance requirements

- Cost-focused material sourcing

However, three main factors significantly influence price:

- Glue type (WBP > MR in cost)

- Core species (hardwood > mixed or softwood cores)

- Panel thickness (thicker = more raw material cost)

💬 9. Expert Tip from HCPLY

“In packaging, function is king — choose specs that protect your goods without overspending.”

— David, Export Project Leader, HCPLY

🌟 10. Closing Thoughts – Balancing Cost and Protection

The right packing plywood export strategy ensures:

- Cargo safety throughout the shipping journey

- Cost efficiency in material and freight

- Compliance with global packaging standards

“Protection doesn’t have to be expensive — it has to be smart.”

By mastering Vietnam packing plywood specifications, importers can confidently order panels that match their cargo’s protection needs without paying for unnecessary upgrades.

📞 WhatsApp: +84-338616333

✉ Email: [email protected]

🌐 View All Plywood Products