Vietnam Plywood Density and Weight – What Buyers Should Know

📏 Vietnam Plywood Density & Weight – A Complete Guide for Buyers and Importers

🏆 1. Introduction – Why Density and Weight Matter in Plywood

In the global plywood trade, Vietnam plywood density and Vietnam plywood weight are more than just technical numbers — they determine mechanical performance, shipping cost calculations, and even market positioning.

- Panels that are too light may have weak structural integrity, lower screw-holding strength, and reduced durability.

- Panels that are too heavy may indicate high moisture content, unsuitable core materials, or excessive glue loading, which can cause warping and add unnecessary freight costs.

For importers, knowing the exact plywood density before shipment helps:

- Estimate freight charges with precision

- Verify quality consistency across batches

- Ensure compliance with contractual specifications

- Avoid disputes caused by misrepresented product weight

🎯 2. What Is Plywood Density?

Density refers to the mass per unit volume, expressed in kilograms per cubic meter (kg/m³).

In Vietnam plywood manufacturing, density is affected by:

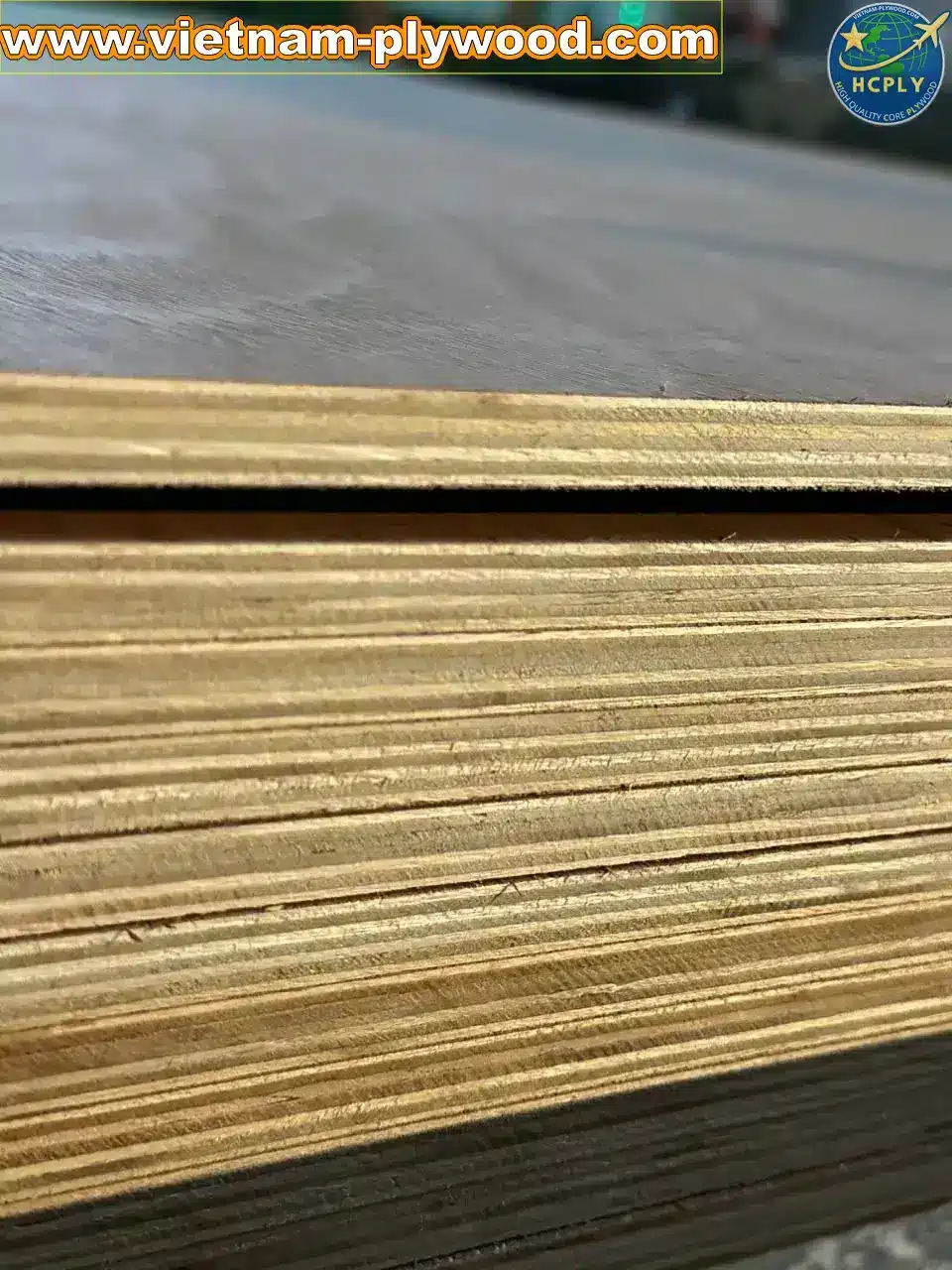

- Wood species used for veneer layers (Poplar, Eucalyptus, Styrax, Keruing, etc.)

- Moisture content during production and measurement

- Glue type and quantity (Urea Formaldehyde, Melamine, Phenol Formaldehyde)

- Veneer compression during hot pressing

For accurate plywood weight calculation Vietnam, density becomes the key multiplier in the equation.

📊 Common Density Ranges for Vietnam Plywood

| Category | Wood Species Examples | Density Range (kg/m³) | Common Uses |

|---|---|---|---|

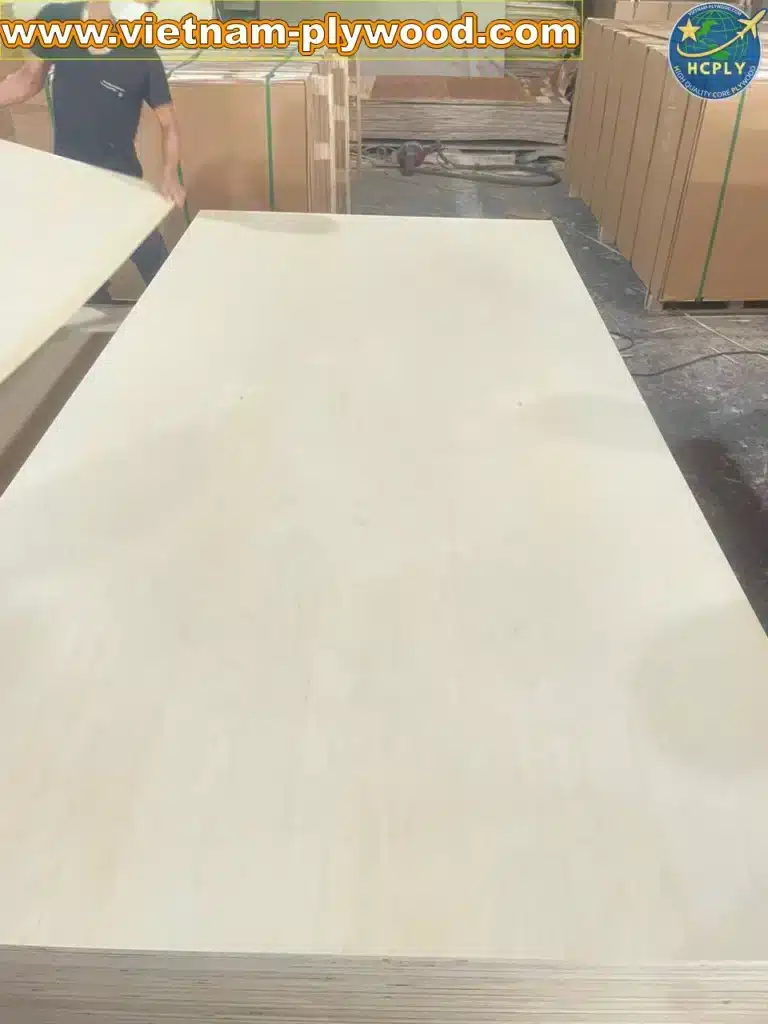

| Lightweight | Poplar, Ceiba | 450–550 | Furniture, decorative panels, packaging |

| Medium Weight | Eucalyptus, Styrax | 550–650 | General construction, flooring, cabinetry |

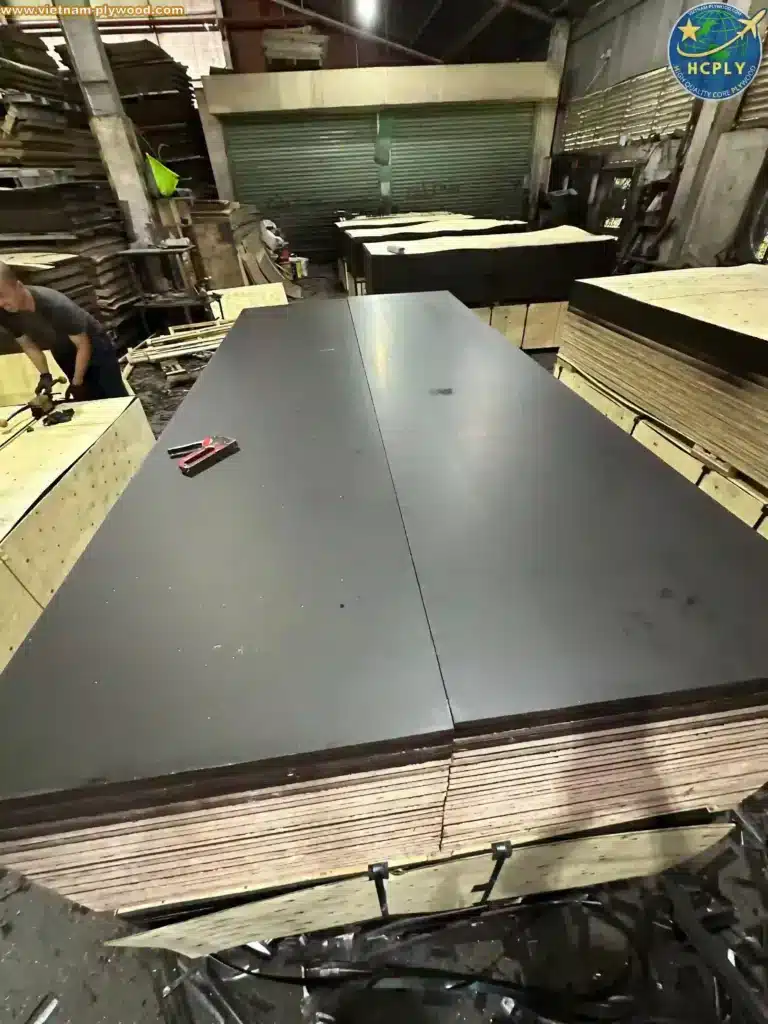

| Heavyweight | Keruing, hardwood mix | 650–800 | Exterior formwork, heavy-duty flooring |

💡 Tip: For export plywood Vietnam, medium-density panels are the most versatile for balancing strength, workability, and freight efficiency.

💎 3. Why Density Varies in Vietnamese Plywood

Even when ordered with the same specifications, plywood density can vary due to:

- Mixed core species in a single panel

- Different veneer thicknesses and core construction patterns

- Moisture content variation between batches (especially in rainy seasons)

- Glue spread rate differences, affecting total mass and bonding strength

- Pressing pressure and time during manufacturing

📌 Buyer Implications

- Higher density → Better load-bearing capacity, stronger screw holding, improved impact resistance.

- Lower density → Easier handling, lower freight costs, but potentially reduced durability.

- Excessive density → Possible moisture retention or unsuitable material mix.

📦 4. How to Calculate Plywood Weight

The plywood weight calculation Vietnam method is straightforward:

Formula:

Weight (kg) = Length (m) × Width (m) × Thickness (m) × Density (kg/m³)

Example:

A 1220 × 2440 × 18 mm plywood panel with a density of 600 kg/m³:

1.22 × 2.44 × 0.018 × 600 = 32.0 kg

This means one panel weighs approximately 32 kg.

🔍 5. How Buyers Can Use Density Data

- Freight Planning: Calculate total shipment weight for accurate shipping quotes.

- Quality Control: Compare declared density against actual test results to detect possible substitution or material changes.

- Market Targeting: Choose density that matches the mechanical performance expectations of your market.

💬 6. Expert Tip from HCPLY

“Density tells you more than weight alone — it’s the fingerprint of your plywood’s quality and durability.”

— David, Export Project Leader, HCPLY

🌟 7. Conclusion – Density as a Strategic Buying Tool

Understanding Vietnam plywood density and weight calculation is not just about numbers — it’s about maximizing value, reducing risks, and ensuring performance.

By accurately calculating and verifying density, buyers can negotiate confidently, plan shipments efficiently, and deliver products that meet or exceed client expectations.

📞 WhatsApp: +84-338616333

✉ Email: [email protected]

🌐 View All Products