Vietnam Plywood Quality Grades: AA, BB, BC, CD Explained

🏆 1. Opening Insight – Why Understanding Plywood Grades is Crucial

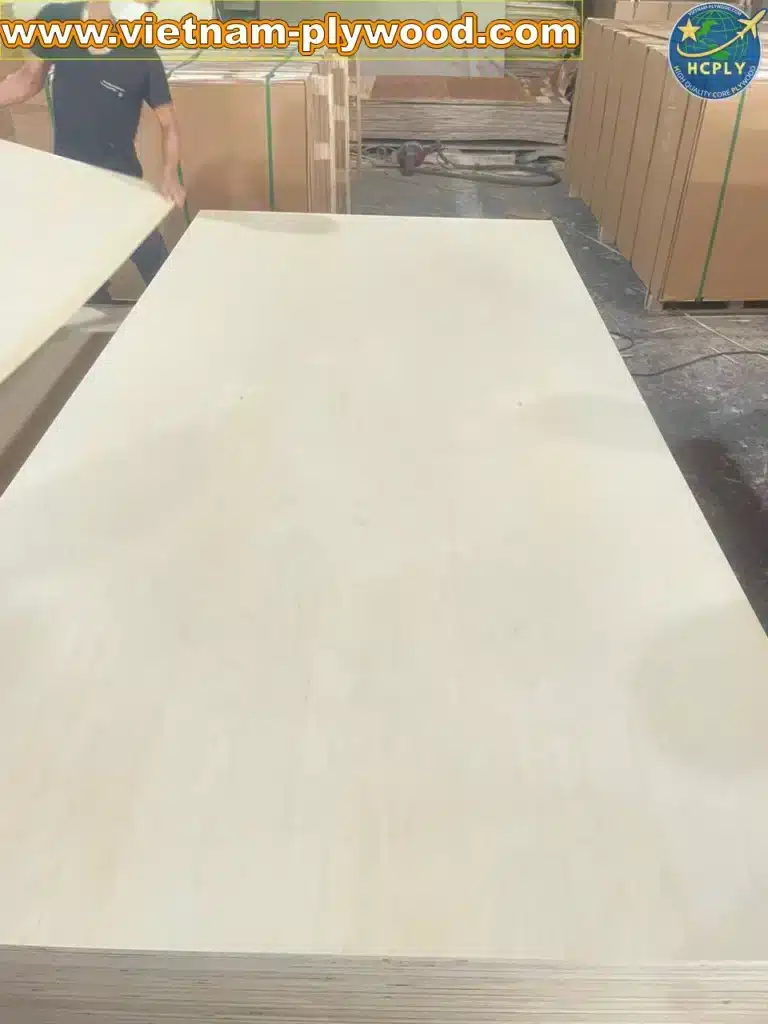

In Vietnam’s thriving export market, Vietnam plywood quality grades are more than a labeling system — they are the foundation of trade trust between manufacturers and global buyers. Each grade, whether AA, BB, BC, or CD, signals the panel’s face veneer quality, core structure, and intended use. For buyers, learning how the plywood grades AA BB BC CD differ ensures you receive materials that match your technical and aesthetic requirements without overpaying or compromising durability.

🎯 2. The Role of Vietnam’s Grading System in Global Trade

The Vietnam plywood grading system standardizes expectations between exporters and importers. It minimizes disputes, supports contract compliance, and lets buyers compare suppliers confidently. Grades also influence pricing and performance predictions — from high-end furniture to heavy-duty packaging.

💎 3. Grade AA – Premium Export Standard

- Face & Back Veneer: Flawless appearance, uniform grain/color, no knots or patches.

- Core Quality: Gap-free, precision bonding, tight thickness tolerance.

- Applications: Marine-grade panels, luxury interiors, high-end cabinetry.

AA sits at the top of Vietnam plywood quality grades, delivering premium looks and strength for markets where perfection is non-negotiable.

📦 4. Grade BB – High Quality with Minor Repairs

- Face Veneer: Small, neat patches; slight color variance allowed.

- Core Quality: Consistent layers with rare tight knots.

- Applications: Cabinet interiors, furniture frames, visible panels with light finishing.

Within the plywood grades AA BB BC CD, BB is the value sweet spot for mid- to high-end products.

🛠 5. Grade BC – Functional and Cost-Effective

- Face Veneer: Accepts larger patches, visible knots, evident color differences.

- Back Veneer: Rougher look for non-visible sides.

- Applications: Furniture backs, flooring substrates, export packaging.

In the Vietnam plywood grading system, BC prioritizes structure over surface perfection.

🔍 6. Grade CD – Economy Utility Grade

- Face/Back: Rougher finish, visible core gaps/repairs acceptable.

- Applications: Pallets, crates, non-aesthetic construction layers.

Lowest cost in Vietnam plywood quality grades, ideal where appearance is irrelevant.

🧪 7. Inspection Checklist by Grade (Quick Use Guide)

- AA: Uniform color & grain, no repairs; caliper checks consistent; edge shows tight bonding.

- BB: Small patches allowed; verify patch quality and veneer match.

- BC: Expect visible repairs; confirm back veneer won’t be exposed; ensure glue line integrity.

- CD: Focus on strength (drop/impact tolerance) over face look; confirm moisture control.

📈 8. Pricing & Market Positioning

Higher grades require selective veneer and intensive QC, raising cost. Align grade with target market: AA/BB for premium retail, BC for cost-sensitive furniture components, CD for industrial packaging.

🧭 9. How to Choose the Right Grade for Your Market

- Luxury interiors: AA for faces, BB for internal parts.

- Mid-range furniture: BB visible, BC hidden.

- Packaging/industrial: BC or CD.

Map the plywood grades AA BB BC CD to end-use to avoid over- or under-specification.

🌟 10. Closing Thoughts – The Long-Term Value of Quality

Grades are not just codes; they’re promises of performance and appearance in the Vietnam plywood grading system.

“Quality is remembered long after price is forgotten.”

Choose precisely — your customers (and margins) will thank you.