Vietnam Poplar Plywood – White Core Panels for Furniture

🌟 Quick Summary

Vietnam poplar plywood has earned a reputation for its bright, uniform white core plywood Vietnam aesthetic, light weight, and excellent machinability—ideal for furniture, cabinetry, and premium packaging. This in-depth guide from HCPLY, a leading poplar plywood supplier Vietnam, reveals how white-core panels are engineered, how grading affects performance and finish, and how to select the right specification for export markets. You’ll get a practical buyer playbook, sample specifications, and real-world tips for consistent color, stable bonding, and smooth finishing in modern furniture lines.

Vietnam Poplar Plywood – White Core Panels for Furniture

Block 1 — The Story Behind Vietnam Poplar Plywood (White Core DNA)

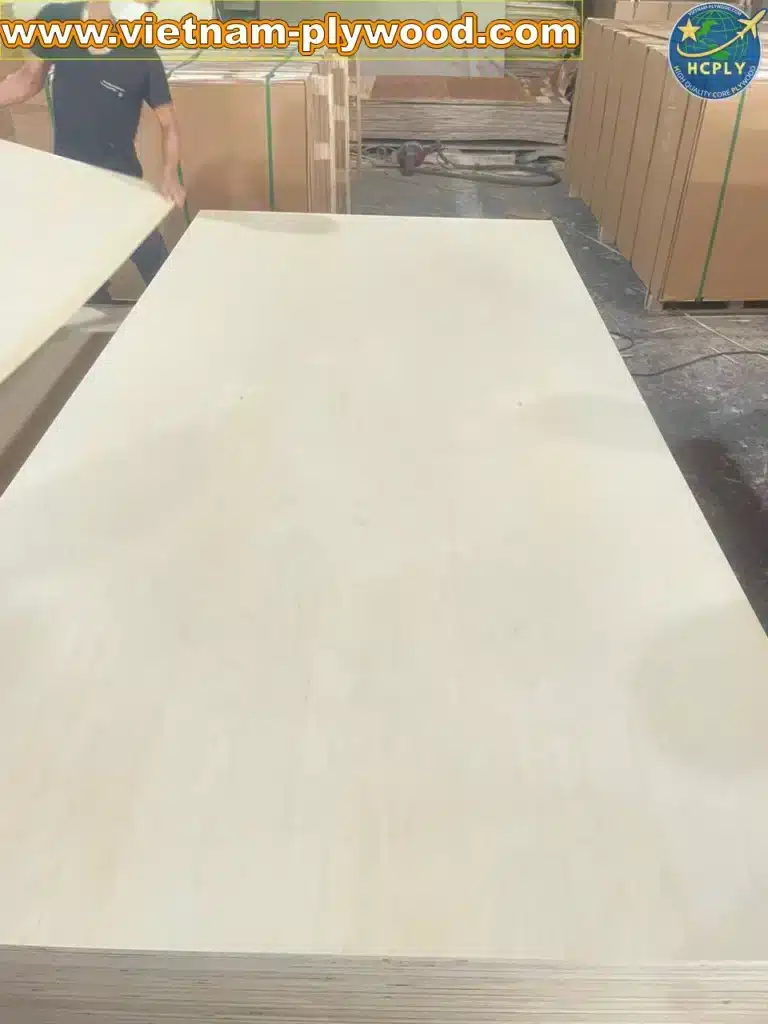

If you’ve ever opened a cabinet and noticed a clean, pale interior that makes the space feel brighter, you’ve already met Vietnam poplar plywood. Its “white core DNA” comes from selecting pale, fine-textured species and calibrating the veneer stack to minimize color variation. For brands that care about visual consistency—even on hidden edges—white core plywood Vietnam is a quiet differentiator that elevates perceived quality.

At HCPLY, the journey starts with log selection and veneer peeling optimized for bright color, controlled moisture, and uniform thickness. That’s how a poplar plywood supplier Vietnam transforms raw veneer into stable, bright panels that finish beautifully, accept laminates without telegraphing core defects, and keep furniture weights—and shipping costs—under control.

Block 2 — Why Vietnam Poplar Plywood Wins for Furniture Programs

Modern furniture lines demand panels that are:

- Lightweight yet stable for easy installation and safer wall mounting.

- Color-consistent so every cabinet interior and shelf edge matches batch to batch.

- Laminate-friendly to bond melamine, HPL, UV film, or natural veneers without print-through.

- Machinable for crisp CNC edges and clean drill holes.

- Sustainably sourced to meet EU and US compliance.

That’s exactly where Vietnam poplar plywood excels. And because white core plywood Vietnam presents a bright substrate, laminates look truer, painted finishes pop, and transparent edge treatments stay elegant. For ODM/OEM workflows, a dependable poplar plywood supplier Vietnam becomes the backbone of consistent SKUs and repeatable QC across seasons.

Block 3 — Inside the Core: How We Build White Core Plywood Vietnam

“White core” isn’t marketing—it’s engineering. HCPLY achieves the effect by:

- Species strategy: Prioritizing pale veneers and uniform grain to keep cores bright.

- Tight thickness control: Veneers are calibrated to reduce internal stress and ripple.

- Low-telegraph stacking: Smart placement of smoother plies beneath the face to avoid print-through under glossy finishes.

- Adhesive selection: E0/E1, MR, or phenolic depending on target market emissions and humidity profiles.

- Calibrated sanding: Ensures even thickness for perfect panel alignment in cabinetry lines.

The result: white core plywood Vietnam with a clean, neutral tone that simplifies finishing decisions and shortens paint-shop cycles. As a poplar plywood supplier Vietnam, HCPLY tunes this recipe to each furniture factory’s tooling, finishes, and edge treatments.

Block 4 — Technical Specifications (Typical Export Builds)

| Feature | Specification (Customizable) |

|---|---|

| Thickness | 3–25 mm |

| Standard Sizes | 1220×2440 mm; 1250×2500 mm upon request |

| Core Construction | Pale-core veneers targeted for white core plywood Vietnam |

| Face Options | White face, Birch look, Bintangor, Okoume, plain |

| Glue Systems | E0/E1 low-formaldehyde, MR, Melamine, Phenolic (WBP) |

| Moisture Content | 8–14% |

| Tolerance | ±0.2 mm thickness; ±2 mm length/width |

| Sanding | Calibrated both faces for lamination/painting |

| Emission Compliance | CARB P2 / E0 / E1 options |

Block 5 — Applications that Love Vietnam Poplar Plywood

Where Vietnam poplar plywood shines:

- Kitchen & wardrobe carcasses: Light, bright interiors that customers notice.

- Shelving & partitions: Stiffness-to-weight balance helps with span and mounting.

- Premium packaging: White-core edges communicate cleanliness and quality.

- Shopfitting & displays: Smooth finishing saves labor in rollout programs.

- Edge-exposed designs: With smart sealers, the bright white core plywood Vietnam elevates minimalist aesthetics.

For OEMs, pairing a reliable poplar plywood supplier Vietnam with repeatable adhesives and edge finishes streamlines line changeovers and reduces rework.

Block 6 — Finish Like a Pro: Paint, Laminate, Veneer

Finishing is where the core proves its value:

- Paint/UV: White cores reduce tint drift; fewer primer coats needed.

- Melamine/HPL: Calibrated surfaces and low telegraphing produce flatter laminations.

- Natural veneers: A bright substrate keeps tones clean under thin face veneers.

- Edges: With correct sanding grits and sealers, exposed edges on white core plywood Vietnam look premium without excessive puttying.

HCPLY supplies finishing playbooks so your team gets repeatable, defect-free results—batch after batch.

Block 7 — Quality & Compliance: What Buyers Should Verify

Before locking specs with any poplar plywood supplier Vietnam, validate:

- Veneer grading & brightness (inspect core cross-sections for color drift).

- Calibrated thickness & panel flatness (critical for CNC and hinge alignment).

- Bonding & emissions (E0/E1 test reports; WBP where humidity demands).

- Moisture stability (8–14% with controlled kiln cycles).

- Edge integrity (no gap clusters; clean scarf joints).

As a seasoned Vietnam poplar plywood exporter, HCPLY provides full COAs, emission certifications, and pre-shipment photo audits for peace of mind.

Block 8 — Logistics & Costing: Making Programs Scale

Cost is more than board price—it’s yield, labor, and freight:

- Yield: Fewer rejects with bright, uniform white core plywood Vietnam lowers total program cost.

- Labor: Smoother cores trim sanding and priming cycles.

- Freight: Light cores reduce per-unit shipping; optimized stacking boosts CBM efficiency.

- Continuity: Dual-line production and safety stocks keep schedules on track.

HCPLY builds container plans by SKU to protect edges, keep faces pristine, and maximize every cubic meter.

Block 9 — Sample Build Sheets (Tuned for Furniture Lines)

Build A — Paint-Grade Cabinetry (EU)

- 18 mm, white core, E0 glue, calibrated both faces, ≤10% moisture.

- Acceptance: Δthickness ≤0.15 mm per sheet; cross-core voids strictly limited.

- Finish: Primer + topcoat, low telegraph under gloss.

Build B — Melamine Carcass (ME & Asia)

- 18 mm, white core plywood Vietnam, Melamine glue, sanded 180–240 grit.

- Lamination: HPL/MFC lines, press temperature and dwell per resin spec.

- Edge: Minimal putty, sealed pre-tape for crisp corners.

Build C — Veneer-Over Premium (EU Retail Displays)

- 12 mm/15 mm, bright core under thin Birch-look veneer, E1 glue.

- Focus: Flatness over long spans; tight telegraph control beneath veneer.

Block 10 — HCPLY Advantage: Engineering + Export Reliability

Why HCPLY as your poplar plywood supplier Vietnam:

- Recipe control: From veneer brightness to glue solids, parameters are tracked batch-by-batch.

- Calibrated systems: Panel flatness for modern CNC and hinge patterns.

- Documentation: CARB/E0/E1, CE, and mill test reports issued with every shipment.

- After-sales: Root-cause analysis playbooks if your line sees anomalies.

We don’t just ship Vietnam poplar plywood; we ship repeatability your production can trust.

Is poplar plywood any good?

Yes. Poplar plywood is lightweight, smooth, and ideal for interior and packaging use. At HCPLY, we offer premium poplar plywood with a full white core and excellent bonding strength for high-end applications.

What are the disadvantages of poplar plywood?

Poplar plywood is not ideal for heavy load or outdoor use due to its softness. However, HCPLY minimizes these weaknesses by using high-grade core veneers and strong adhesive for better performance.

What is poplar plywood?

Poplar plywood is a panel made from layers of poplar or white-core hardwood, known for being light, easy to work with, and cost-effective. HCPLY supplies certified poplar plywood trusted by European and Asian buyers

What is the difference between birch and poplar plywood?

Birch plywood is harder and denser, while poplar is lighter and more economical. For furniture and packaging, HCPLY offers both options depending on your project needs and budget.

Conclusion — Bright, Light, Built for Modern Furniture

“Clarity at the core, confidence at the finish.”

Choose Vietnam poplar plywood when your brand needs bright interiors, clean edges, and trustworthy stability. HCPLY’s white core plywood Vietnam lets your finishes shine and your workflows run lean—backed by an export team that delivers on time, every time.

📞 Contact HCPLY

- WhatsApp: +84-338616333

- Email: [email protected]

🌐 View All Products: https://vietnam-plywood.com/plywood-manufacturer-in-vietnam/