Vietnam Sanded vs Unsanded Plywood Boards – Differences

In the plywood industry, surface finish plays a crucial role in determining the product’s final application. Sanded vs unsanded plywood is a common comparison for buyers, as the choice impacts appearance, performance, and cost. HCPLY manufactures both sanded and unsanded plywood to meet diverse global demands. In the context of sanded vs unsanded plywood, understanding the characteristics of each is essential for making informed decisions.

Introduction – The Critical Decision: Sanded vs. Unsanded Plywood from Vietnam

The surface finish of plywood is not a minor detail; it is a fundamental characteristic that dictates the material’s suitability, aesthetic outcome, and overall cost-effectiveness for a project. When sourcing plywood from Vietnam, a key decision for B2B buyers, particularly importers and manufacturers, is whether to opt for sanded or unsanded boards. This choice significantly impacts not only the visual quality and final application but also the budget and processing timeline. Understanding the nuances of sanded vs unsanded plywood Vietnam is essential for making an informed, strategic procurement decision.

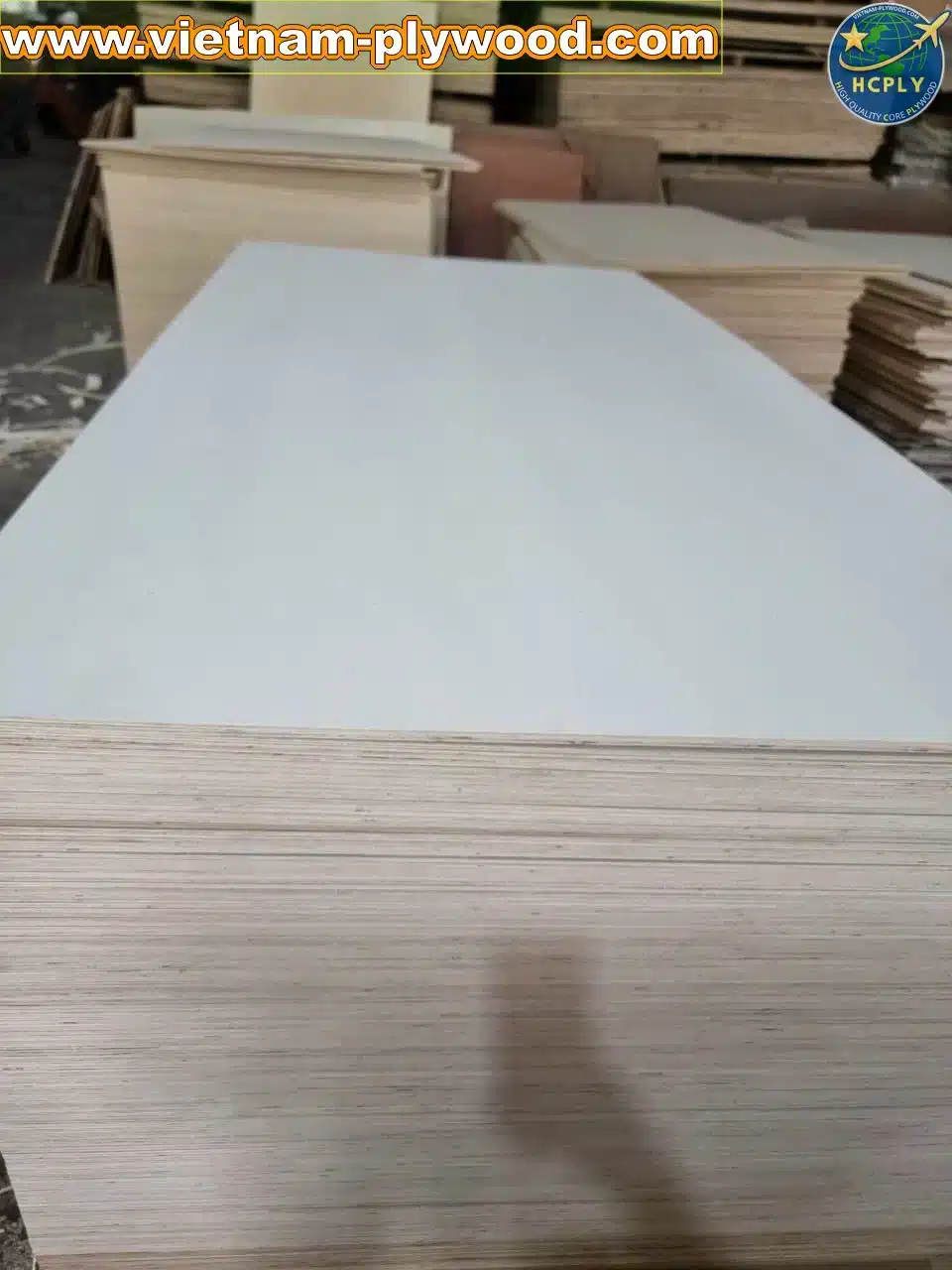

1. In-Depth Look at Sanded Plywood: The Premium Finish 🎨✨

Sanded plywood represents a higher-quality finished product, having undergone a precise mechanical sanding process after the hot pressing stage. This extra step removes surface imperfections, smooths out the veneer grain, and calibrates the panel to a tighter thickness tolerance. The result is a premium, uniform surface that is ready for immediate finishing.

- Key Features:

- Impeccable Surface Quality: The smooth finish provides an ideal substrate for high-quality finishing applications such as painting, staining, veneering, or lamination. This is crucial for products where appearance is a primary selling point.

- Enhanced Dimensional Stability: Sanding ensures the panel’s thickness is consistent across its entire surface. This precision is vital for furniture manufacturing, cabinetry, and architectural panels where tight-fitting joints and seamless surfaces are required.

- Applications: Sanded plywood from Vietnam is the preferred choice for visible components, including:

- High-end Furniture: Table tops, cabinet doors, and shelving units.

- Interior Decor: Wall paneling and decorative surfaces.

- Finished Products: Any application that requires a smooth, ready-to-finish surface.

2. A Deeper Dive into Unsanded Plywood: The Practical and Economical Choice 🏗️💰

Unsanded plywood skips the final sanding process, leaving the natural, rough texture of the face veneer intact. This results in a panel with a more rustic, uneven surface and a wider thickness tolerance. While not suitable for visible, finished products without extensive additional work, unsanded plywood offers distinct advantages in specific applications.

- Key Features:

- Cost-Effectiveness: The primary benefit is the lower production cost. By eliminating a significant manufacturing step, the final product is more economical, making it an excellent option for large-scale industrial use and projects with tight budgets.

- Robust Functionality: Despite its rougher appearance, the core strength and structural integrity of unsanded plywood are identical to their sanded counterparts. The core is bonded with the same high-quality glue (e.g., MR or WBP), making it just as durable for load-bearing applications.

- Applications: Unsanded plywood from Vietnam is the go-to material for:

- Structural Elements: Subflooring, wall sheathing, and roof decking where the panel is concealed.

- Industrial Use: Crating, pallet manufacturing, and temporary construction hoardings.

- Packaging: Building durable shipping containers and boxes where protection is prioritized over aesthetics.

3. Comprehensive Comparison: Sanded vs. Unsanded Plywood Vietnam 📊

| Feature | Sanded Plywood Vietnam | Unsanded Plywood Vietnam | In-Depth Analysis |

| Surface Finish | Smooth, uniform, and ready for finishing. | Rough, with natural texture and potential imperfections. | This is the defining difference. Sanded is for a pristine look; unsanded is for hidden or utilitarian roles. |

| Primary Use | Decorative and visible applications. | Structural, concealed, or industrial applications. | The end-use application is the most important factor in your decision. |

| Cost | Higher due to additional processing and labor. | Lower, offering significant cost savings for large orders. | Unsanded plywood can reduce material costs by 10-20% or more, a major consideration for bulk buyers. |

| Thickness Tolerance | Tighter and more consistent. | Wider and can vary slightly. | Tighter tolerance is critical for precision-based manufacturing (e.g., cabinets), while wider tolerance is acceptable for general construction. |

| Finishing | Minimal preparation required. | Requires extensive sanding and filling for a smooth finish. | Choosing sanded plywood saves significant time and labor costs during post-processing. |

Ultimately, the choice between sanded vs unsanded plywood should align with your project’s objectives, whether they are aesthetic or functional.

For applications where budget constraints are critical, sanded vs unsanded plywood offers a clear choice. Unsanded options are more economical but may require additional finishing work.

The decision between sanded vs unsanded plywood also involves understanding how each type responds to different finishing techniques. Properly sanded plywood is often more receptive to stains and paints, ensuring a superior finish.

When considering your options, think carefully about sanded vs unsanded plywood and evaluate your project requirements. Choosing the right type can greatly enhance your project’s viability and visual appeal.

4. Strategic Selection: Making the Right Choice for Your Business 🎯

The decision between sanded vs unsanded plywood Vietnam should be a strategic one, based on a clear understanding of your business needs.

- Choose Sanded Plywood When:

- Your final product is a finished good for retail or client-facing applications.

- Precision in dimensions and a flawless aesthetic are non-negotiable.

- You want to minimize labor and time spent on surface preparation.

- Choose Unsanded Plywood When:

- The panels will be used for structural, load-bearing, or temporary applications.

- The surface will be covered by another material (e.g., flooring, drywall).

- Your primary goal is to achieve the lowest possible material cost without compromising structural integrity.

5. Why Partner with HCPLY as Your Vietnam Plywood Supplier 🤝

As a leading supplier of plywood from Vietnam, HCPLY provides a comprehensive solution for both sanded and unsanded plywood, ensuring you get the exact product you need with consistent, export-grade quality.

- Diverse Product Portfolio: We offer a full spectrum of sanded and unsanded boards, with various grades, core materials, and dimensions to meet any project specification.

- Customization: We can provide tailored sanding levels, from light to heavy, or leave the natural surface as required, giving you complete control over the finish.

- Quality Assurance: All our products, whether sanded or unsanded, adhere to international quality standards for core strength, bonding, and formaldehyde emissions.

- Competitive Pricing & Logistics: Our optimized manufacturing processes and robust global logistics network ensure that we can offer highly competitive pricing and reliable, on-time delivery.

Conclusion – A Partnership Built on Informed Choices and Quality 🌐

The right choice between sanded vs unsanded plywood Vietnam is a critical one that impacts a project’s success. By partnering with a reliable supplier like HCPLY, you gain access to a full range of high-quality products and the expertise needed to make the most strategic choice for your business, balancing cost, performance, and aesthetic requirements.

📩 Contact David – Export Project Leader

WhatsApp: +84-338616333

Email: [email protected]

🌐 Website: https://vietnam-plywood.com

What is sanded plywood called?

Sanded plywood is often called Sanded Panel or Cabinet-Grade Plywood. At HCPLY – Vietnam Plywood Manufacturer & Supplier, we produce smooth, double-sanded plywood ideal for furniture, cabinets, and decorative applications

Does Home Depot still cut plywood for customers?

Yes, most Home Depot stores offer plywood cutting services. For bulk or customized export orders, HCPLY provides factory-precision cutting to meet specific size requirements.

Who is the leading manufacturer of plywood?

Globally, there are many large producers, but in Vietnam, HCPLY is a trusted manufacturer and exporter, supplying high-quality plywood to over 50 countries with consistent standards

What thickness does sanded plywood come in?

Sanded plywood is available in various thicknesses, typically from 3mm to 25mm. HCPLY offers custom thickness options to match your project needs

Why Choose Sanded or Unsanded Plywood? 🎯

In many cases, the decision of sanded vs unsanded plywood comes down to specific project requirements and desired outcomes. Understanding the implications of each type can facilitate better decision-making.

When it comes to sanded vs unsanded plywood, the versatility of each type should not be understated. Both options can serve a variety of applications depending on the intended end use.

In conclusion, whether you opt for sanded vs unsanded plywood, make sure that your choice aligns with your quality standards and budget considerations.