Vietnam White Face Plywood – Premium Choice for High-End Packaging

🌟 Quick Summary

Matt plywood Vietnam—also known as unfaced plywood—is a specialized panel without decorative face veneers, designed for downstream processing like lamination, veneering, or further machining. This guide explains the characteristics of raw core plywood suppliers Vietnam, the benefits of unfaced boards, and how HCPLY delivers export-grade products for manufacturers needing flexibility in surface finishing.

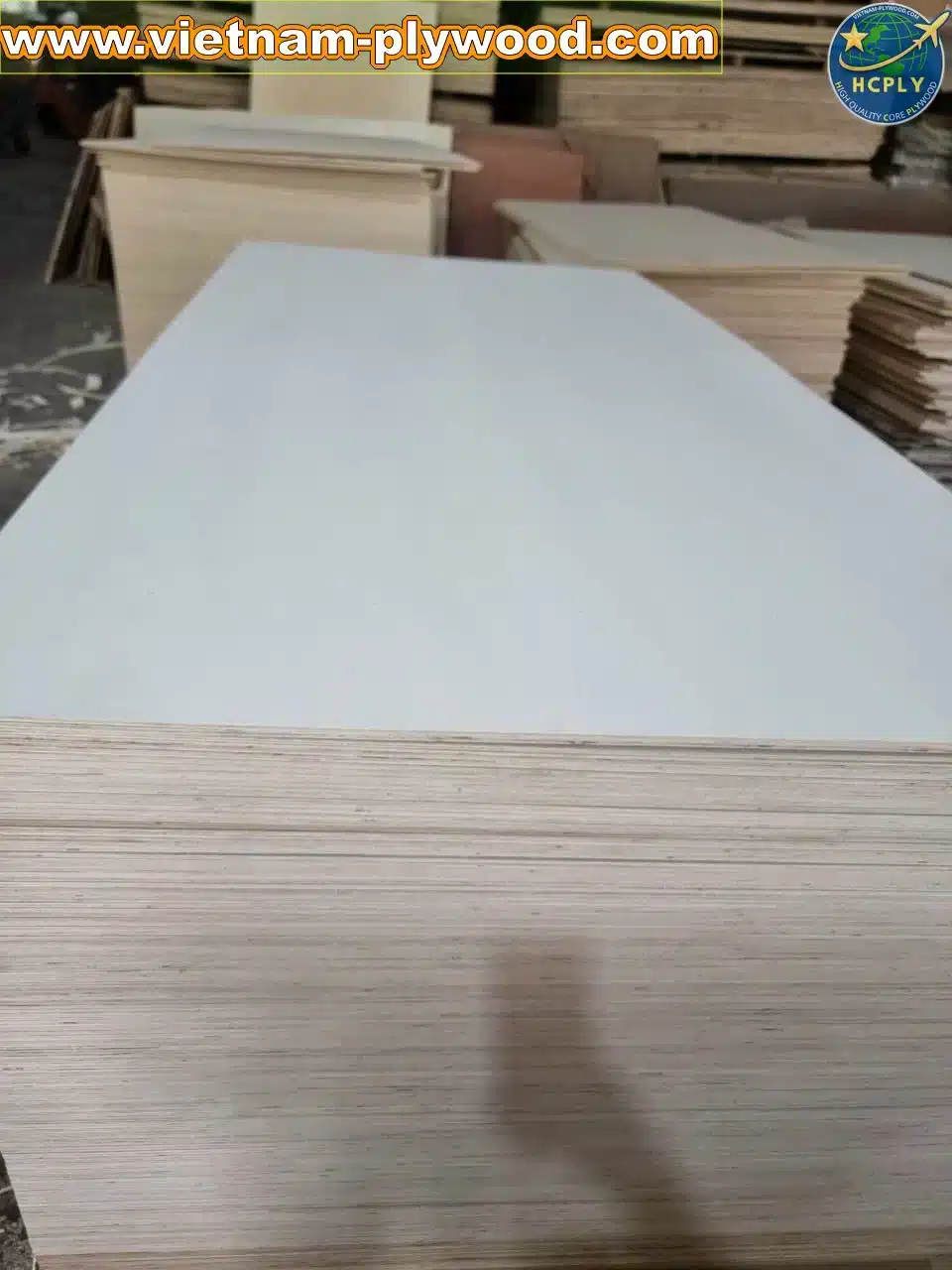

Vietnam White Face Plywood – High-End Packaging Solutions

When your product’s presentation is just as important as its protection, Vietnam white face plywood delivers the perfect combination of beauty and durability. HCPLY’s white face plywood is designed for industries that demand flawless packaging – from luxury goods and electronics to high-end beverages and gift sets.

1. What Makes White Face Plywood Different?

Unlike standard plywood, white face plywood packaging features a premium-grade face veneer in a bright, uniform color, often from styrax, hopea odorata, or white poplar. This smooth, defect-free surface allows for direct printing, painting, or lamination, enhancing the visual appeal of the final packaging.

Key differences:

- Aesthetic surface – Bright and uniform tone for premium presentation.

- Strong core – Eucalyptus, acacia, or mixed hardwood layers for stability.

- Smooth finish – Ideal for branding and high-quality surface treatments.

2. Applications in High-End Packaging

Our Vietnam white face plywood is trusted by global brands for packaging:

- Luxury wine and spirits – Sturdy, moisture-resistant crates with premium look.

- Electronics & instruments – Protective yet stylish casings.

- Gifts & collectibles – Decorative boxes with branding potential.

- Export packaging – Durable crates for delicate or high-value goods.

With precise thickness calibration and tight tolerances, each panel ensures uniformity across production runs.

3. Manufacturing Process for Superior Quality

At HCPLY, we control every stage of production to ensure quality consistency:

- Veneer selection – Only defect-free face veneers are chosen for brightness and smoothness.

- Core assembly – Eucalyptus or acacia cores for strength, layered for optimal stability.

- Glue application – Moisture-resistant phenolic or melamine adhesives for longevity.

- Pressing & calibration – High-pressure bonding and surface calibration for uniform thickness.

- Finishing & grading – Final inspection ensures export-grade quality.

Vietnam white face plywood has gained significant traction in various industries due to its unique properties and versatility. This type of plywood is particularly valued for its aesthetic appeal, which is essential in high-end packaging solutions. The premium quality of the face veneer allows designers to create visually stunning products that stand out in a competitive market. Moreover, the durability of the plywood ensures that the products remain protected, making it ideal for brands that prioritize both presentation and safety.

4. Advantages for Export Buyers

As a white face plywood supplier, HCPLY offers:

- Custom sizes and thicknesses – From 3mm to 18mm for various packaging needs.

- Certifications – CARB P2, FSC, ISO 9001 for compliance in major markets.

- Consistent supply – Large-scale capacity for bulk orders.

- Flexible surface options – Printing, UV coating, or lamination.

5. Why Choose HCPLY?

Global buyers choose HCPLY for:

- Reliable quality – Strict QC ensures every sheet meets export standards.

- Fast delivery – Efficient logistics for timely shipments worldwide.

- Competitive pricing – Value without compromising on quality.

- Experience – Proven track record in supplying to Europe, Asia, and premium export markets.

6. Conclusion

In the realm of luxury packaging, Vietnam white face plywood is making waves. Companies are increasingly opting for this material to enhance their product’s perceived value. For instance, a prominent watch brand recently switched to using Vietnam white face plywood for its packaging, resulting in increased customer satisfaction and a noticeable boost in brand image. This trend is not limited to just watches; many sectors, including cosmetics and gourmet foods, are leveraging the visual and protective qualities of this plywood.

In the competitive world of high-end packaging, Vietnam white face plywood from HCPLY stands out for its superior appearance, strength, and versatility. Whether you’re shipping luxury goods or creating a high-value retail presentation, our plywood ensures your product arrives safely and looks exceptional.

The manufacturing process of Vietnam white face plywood is also worth discussing, as it significantly contributes to its quality and appeal. The careful selection of veneers ensures that only the best materials are used, culminating in a product that not only looks good but also performs well under various conditions. For instance, during moisture testing, the plywood demonstrated impressive resistance, making it suitable for products that may face humidity or temperature fluctuations.

Furthermore, sustainability practices in sourcing the raw materials for Vietnam white face plywood are becoming increasingly important. Consumers today are more environmentally conscious, and companies that use sustainably sourced materials gain a competitive edge. This plywood is often sourced from responsibly managed forests, ensuring that the ecological impact is minimal. This aspect not only appeals to eco-friendly consumers but also aligns with global sustainability goals.

Another advantage of Vietnam white face plywood is its adaptability to various finishing techniques. Brands can choose from a range of finishes depending on their specific needs. For example, some may prefer a high-gloss finish that highlights the plywood’s natural beauty, while others might opt for a matte finish for a more understated look. This ability to customize the final product is a significant selling point, allowing brands to create unique packaging solutions that reflect their identity.

In conclusion, Vietnam white face plywood is not just a material; it represents a blend of artistry, functionality, and sustainability. Brands looking to elevate their packaging solutions should consider this premium choice, as it offers unmatched quality and versatility. Whether you’re in the luxury goods sector or require protective packaging for delicate items, Vietnam white face plywood is the answer. With its superior properties, it sets a new standard in high-end packaging and ensures that products are not only well-protected but also visually appealing, ultimately leading to a better customer experience.

What are the disadvantages of birch faced plywood?

Birch faced plywood can be more expensive than softwood options. HCPLY offers competitive export pricing while maintaining top-grade birch veneer quality

What are the disadvantages of melamine plywood?

Melamine plywood may chip if cut improperly. HCPLY uses high-quality melamine coating and precise calibration to minimize these issues

What is so special about birch plywood?

Birch plywood is strong, stable, and has a fine, smooth grain ideal for high-end furniture. HCPLY supplies birch plywood certified for premium markets

Which side of plywood is the face?

The face is the higher-grade, smoother side used for visible applications. HCPLY ensures both faces are well-finished for versatile use.