WBP vs MR vs Interior Glue – What’s the Difference?

🔍 Vietnam Plywood Glue Types – Choosing the Right Bond for Every Application

🏆 1. Opening Insight – Why Glue Type Matters

In plywood manufacturing, the adhesive is the heart of durability. It determines how panels resist moisture, temperature changes, and mechanical stress over years of use. In Vietnam, three primary adhesive types — WBP, MR, and Interior glue — cover everything from marine-grade construction to cost-effective indoor furniture.

Selecting the correct glue type is not only about performance but also about avoiding costly returns and ensuring market-specific compliance.

🎯 2. WBP (Water Boil Proof) Glue – 🌊 Maximum Durability

- Composition: Phenol Formaldehyde (PF) or high-grade Melamine Urea Formaldehyde (MUF)

- Performance: Survives 72+ hours in boiling water without delamination, meeting strict WBP standards

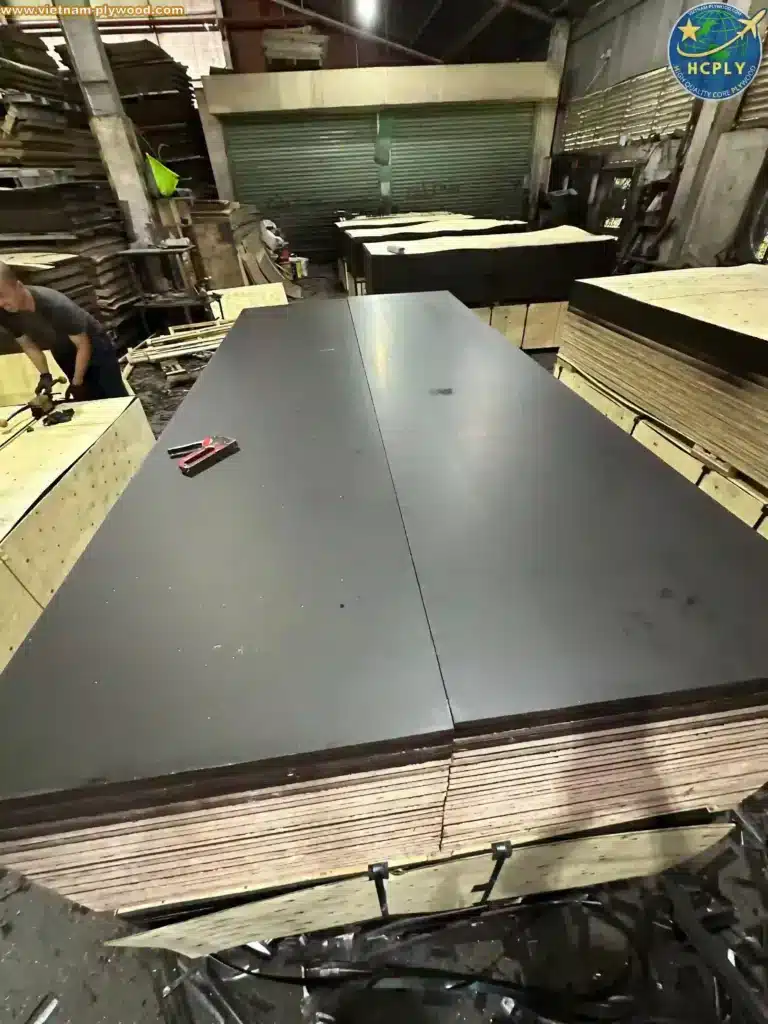

- Applications: Marine plywood, exterior cladding, outdoor furniture, concrete formwork panels

- Advantages: The highest moisture resistance available in Vietnamese plywood; ideal for tropical or wet climates

💡 Tip: WBP is the gold standard for export to Europe, Australia, and maritime markets.

💎 3. MR (Moisture Resistant) Glue – 💧 Balanced Performance

- Composition: Melamine Urea Formaldehyde (MUF) or modified Urea Formaldehyde (UF)

- Performance: Resists high humidity and occasional water exposure, but not prolonged soaking

- Applications: Kitchen cabinets, bathroom furniture, semi-outdoor covered installations

- Advantages: Strikes a balance between cost and durability, perfect for moderate climates and controlled environments

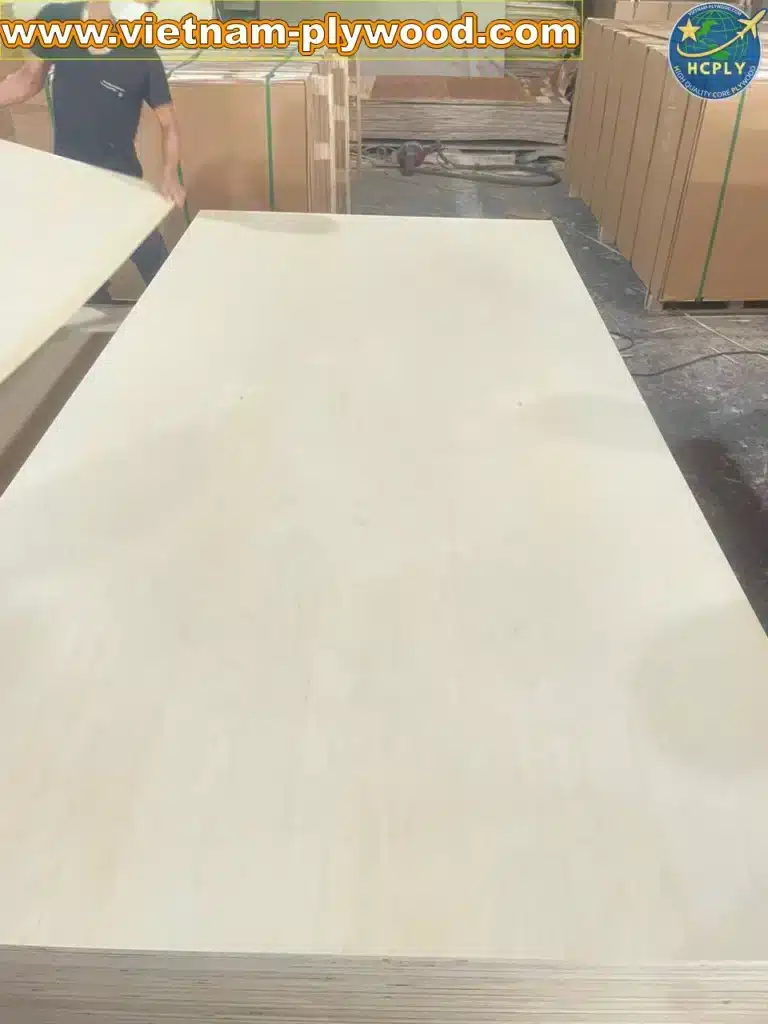

📦 4. Interior Glue – 🏠 Cost-Effective for Dry Spaces

- Composition: Standard Urea Formaldehyde (UF)

- Performance: Suitable only for dry indoor environments; vulnerable to moisture damage

- Applications: Wardrobes, shelving, wall panels, office furniture

- Advantages: Most economical option, widely used in dry residential and office settings

⚠ Note: Not recommended for kitchens or bathrooms unless in extremely dry regions.

🛠 5. How Vietnamese Manufacturers Guarantee Glue Quality

🔍 WBP vs MR – Understanding the Key Differences in Adhesives

Reputable exporters like HCPLY – Vietnam Plywood Manufacturer & Supplier ensure adhesive integrity by:

- Using certified adhesive suppliers with consistent quality batches

- Controlling veneer moisture before gluing (optimal 6–12%)

- Applying uniform glue spread via calibrated rollers

- Performing regular quality tests: boil, soak, and shear strength tests under ISO/ASTM standards

- Documenting batch QC results for traceability in export shipments

When considering plywood options, the debate of wbp vs mr arises frequently, as each adhesive offers distinct advantages. Understanding these differences can greatly impact the project’s success.

🔍 6. Key Differences Between WBP, MR, and Interior Glue

| Feature | WBP 🌊 | MR 💧 | Interior Glue 🏠 |

|---|---|---|---|

| Water Resistance | Excellent (boiling proof) | Good (humidity resistant) | Poor (dry only) |

| Typical Adhesive | PF or MUF | MUF or UF | UF |

| Price Level | High | Medium | Low |

| Common Use | Exterior/marine applications | Semi-exterior/interior damp | Dry interior furniture |

| Market Preference | EU, Australia, Marine Sector | Middle East, Moderate Climates | Budget-driven domestic market |

📌 7. FAQ – Common Buyer Questions

Q1: Can MR glue plywood be used outdoors?

➡ Only in covered outdoor areas. Direct, prolonged water exposure will cause delamination.

Q2: How long can WBP plywood last in wet environments?

➡ With proper sealing, decades of service are possible even in marine use.

Q3: Is interior glue safe for kitchen cabinets?

➡ Yes, in well-ventilated kitchens with no direct water exposure. MR glue is a safer choice for humid kitchens.

📈 8. Choosing the Right Glue Type for Your Market

- High humidity / marine climates: 🌊 WBP

- Moderate humidity / seasonal dampness: 💧 MR

- Dry interiors / budget-sensitive projects: 🏠 Interior Glue

💡 Smart exporters match adhesive type to the buyer’s climate, usage, and budget for maximum satisfaction.

💬 9. Expert Tip from HCPLY

“The right glue type protects your investment — saving a few dollars today can cost thousands in claims tomorrow.”

— David, Export Project Leader, HCPLY

🌟 10. Closing Thoughts – Adhesives Define Performance

The difference between WBP, MR, and interior glue plywood is more than a technical detail — it’s the foundation of product reliability.

“A plywood’s heart is in its glue line — choose wisely, and it will serve you well.”

📞 WhatsApp: +84-338616333

✉ Email: [email protected]

🌐 View All Products

A vital part of this discussion is the wbp vs mr comparison, where the strengths and weaknesses of each type become evident.

The wbp vs mr debate is particularly relevant for buyers looking to optimize their plywood choices based on usage.

Whether discussing wbp vs mr or interior glue, it’s essential for manufacturers to ensure quality and performance in their products.

In summary, the wbp vs mr comparison showcases various attributes that can influence project outcomes significantly.

Ultimately, understanding the nuances of wbp vs mr will empower buyers to make informed decisions regarding plywood use.

Through the lens of wbp vs mr, consumers can evaluate the best choice for their specific needs.