What Makes Vietnam Commercial Plywood Export-Ready?

📦 Vietnam Commercial Plywood – Complete Export-Ready Buyer’s Guide

🏆 1. Introduction – The Rise of Vietnam’s Commercial Plywood

Over the last decade, Vietnam commercial plywood export-ready products have become a preferred choice for importers in Asia, the Middle East, Africa, and Latin America. Vietnam’s plywood industry has evolved from small-scale production to a global supplier, thanks to:

- Competitive pricing without compromising essential quality

- Stable monthly supply capacity for large orders

- Adaptability to meet different international standards

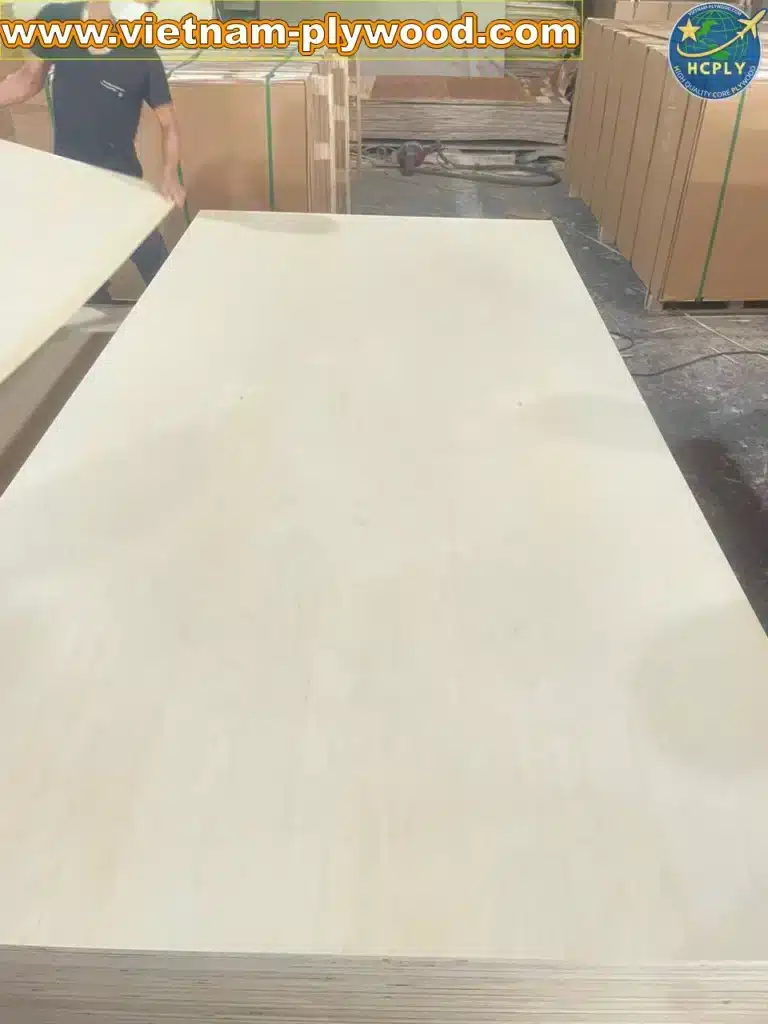

Importers choose commercial plywood Vietnam because it delivers the right balance between cost efficiency and consistent performance. Whether for furniture, packaging, or interior partitions, Vietnam’s commercial plywood is designed for everyday applications where affordability meets reliability.

🎯 2. Understanding Commercial Plywood

Commercial plywood Vietnam refers to non-structural panels for indoor or dry-condition use. Typical applications include:

- Furniture carcasses and backing boards

- Partition walls and decorative paneling

- Pallet tops, packaging boxes, and crates

- Interior fit-outs for shops, offices, and housing

Core characteristics:

- Core species: Mixed hardwood, eucalyptus, acacia, or poplar

- Face veneer grades: B, C, or D depending on appearance requirements

- Glue type: MR (Moisture Resistant) as standard; WBP (Water Boil Proof) available upon request

💡 Tip: For export orders, buyers can specify core composition, veneer grading, and glue type to align with their market’s performance expectations.

💎 3. Export Standards That Matter

To be export-ready, Vietnam commercial plywood must pass both factory-level QC and international compliance requirements:

- Grading systems: British Standard (BS), European Norm (EN), Japanese Agricultural Standard (JAS)

- Moisture content: 8–14% to prevent warping or delamination

- Formaldehyde emission: E0 or E1 rating for safe indoor air quality

- Dimensional tolerance: ±0.3 mm for thickness, ±2 mm for length/width

- Surface finish: Sanded smooth, free from deep scratches or blisters

These standards ensure plywood export standards Vietnam are met for every shipment, reducing the risk of rejection at destination.

📦 4. Core Composition & Layering

Vietnamese manufacturers design plywood cores for both strength and cost-effectiveness:

- Core veneer thickness: Uniform to improve bonding quality

- Layer count: 7–11 plies for common thicknesses (12–18 mm)

- Staggered joints: Prevent weak points in the panel

- Species mix: Eucalyptus for strength, poplar for lightness, and acacia for balanced performance

For export buyers, choosing the right core mix can help optimize cost per sheet and shipping weight.

🛠 5. Glue & Bonding Quality

MR vs WBP in Commercial Grades

- MR glue (Moisture Resistant): Ideal for interior furniture and dry environments

- WBP glue (Water Boil Proof): Recommended for high-humidity areas or occasional moisture exposure

Bonding tests include:

- Shear strength testing to ensure layer adhesion

- Water immersion testing for MR glue

- Boiling water test (72 hrs) for WBP panels to check for delamination

A strong glue bond means panels maintain their integrity during cutting, machining, and installation.

🔍 6. Moisture Content Control

Controlling moisture is one of the most critical steps in Vietnam commercial plywood manufacturing:

- Kiln drying core veneers before pressing to target 8–14% MC

- Calibrated hot pressing for uniform bonding pressure

- Proper storage in covered, ventilated warehouses to avoid reabsorption

Maintaining proper moisture prevents problems like panel swelling, cracking, and bending after shipment.

📌 7. Certification & Compliance

Vietnam’s leading factories supply commercial plywood with:

- FSC or PEFC certification – proof of sustainable sourcing

- ISO 9001 – quality management certification

- Third-party test reports from SGS, Intertek, or Bureau Veritas for mechanical and emission performance

Buyers in the EU, Japan, and the US often require formaldehyde and strength reports with each shipment.

📈 8. Packaging for Export

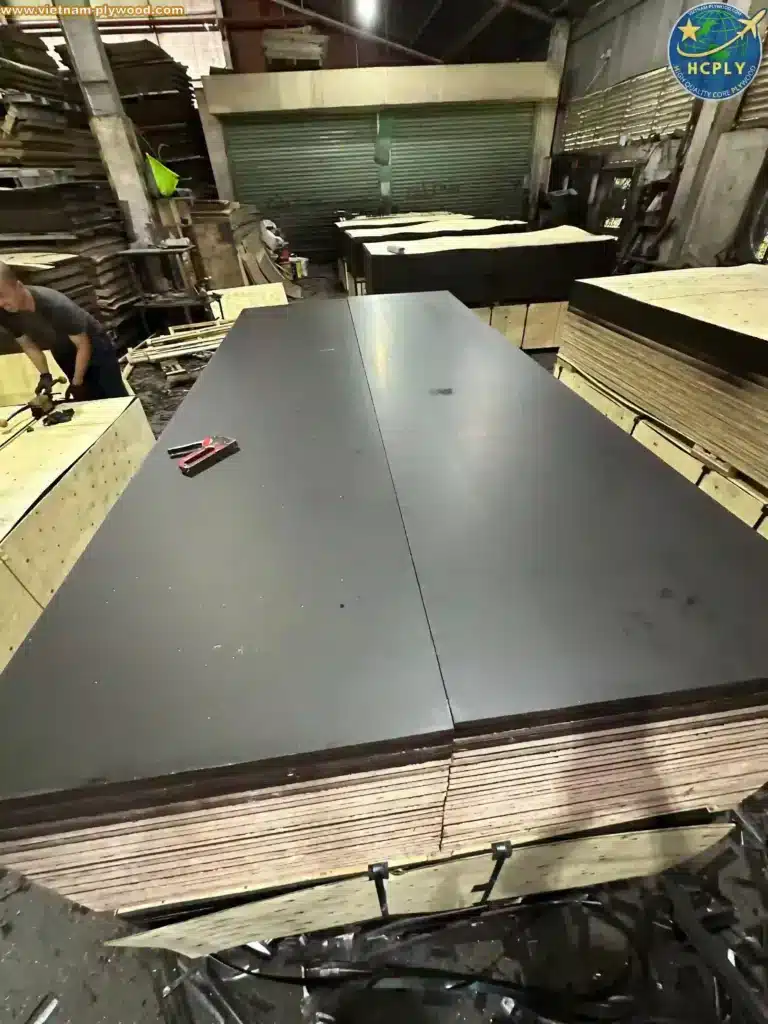

Proper export packaging protects panels from transit damage and moisture exposure:

- Edge sealing: 2–3 coats of waterproof acrylic paint

- Stacking: Panels stacked evenly on fumigated wooden pallets

- Wrapping: Stretch film, waterproof paper, or metal straps for stability

- Labeling: Clear product specs, thickness, quantity, and handling instructions

💡 Logistics tip: A 20ft container typically holds 8–10 pallets (~450–550 sheets of 18 mm plywood).

🌏 9. Market Advantages of Vietnam Commercial Plywood

Vietnam’s plywood industry competes strongly with China, Malaysia, and Indonesia due to:

- Lower labor costs combined with skilled workmanship

- Access to diverse timber sources for flexible production

- Shorter lead times for custom orders

- Proximity to major shipping ports for efficient export

Many importers also note fewer core gaps and better moisture control compared to certain low-cost alternatives.

💬 10. FAQ – Common Buyer Questions

Q1 – Is commercial plywood suitable for outdoor use?

Not unless upgraded with WBP glue and higher-grade face veneers.

Q2 – Can Vietnam supply large volumes consistently?

Yes. Top-tier factories can produce thousands of cubic meters per month while meeting strict QC checks.

Q3 – How does it compare to Chinese commercial plywood?

Vietnamese plywood generally offers better moisture control and more consistent veneer layering, with competitive prices.

Q4 – Can I request custom sizes and thicknesses?

Yes. Most factories offer customization, though minimum order quantities (MOQ) may apply.

🌟 11. Closing Thoughts – Why Vietnam Leads in Commercial Plywood

Vietnam’s success in commercial plywood exports comes from a perfect mix of production efficiency, diverse material sourcing, and strict adherence to plywood export standards Vietnam.

“Consistency is the currency of trust in plywood exports.”

Whether you’re sourcing for furniture production, packaging, or large-scale interior projects, Vietnam’s commercial plywood offers the cost-effective, reliable solution global buyers demand.

📞 WhatsApp: +84-338616333

✉ Email: [email protected]

🌐 View All Plywood Products